Formulation development always throws up new challenges that are tackled via long processes of trial and error work before you can turn your powder into pellets.

To get the answers to your questions and carry out these processes, usually you would need to purchase a lot of different equipment from multiple manufacturers and go through a long and extensive trial and error process reach the ideal formulation parameters. However, finding the right machinery and formulation parameters can be difficult, expensive and time consuming.

As a solution to these problems, Caleva present 3 purpose built pieces of laboratory equipment, designed to take you from not knowing how much binder to add to your dry powder, all the way to usable coated pellets.

Here's how it all works:

Rheology

Rheology

Quantify the characteristics of your wet mass to correctly determine the end point of your granulation

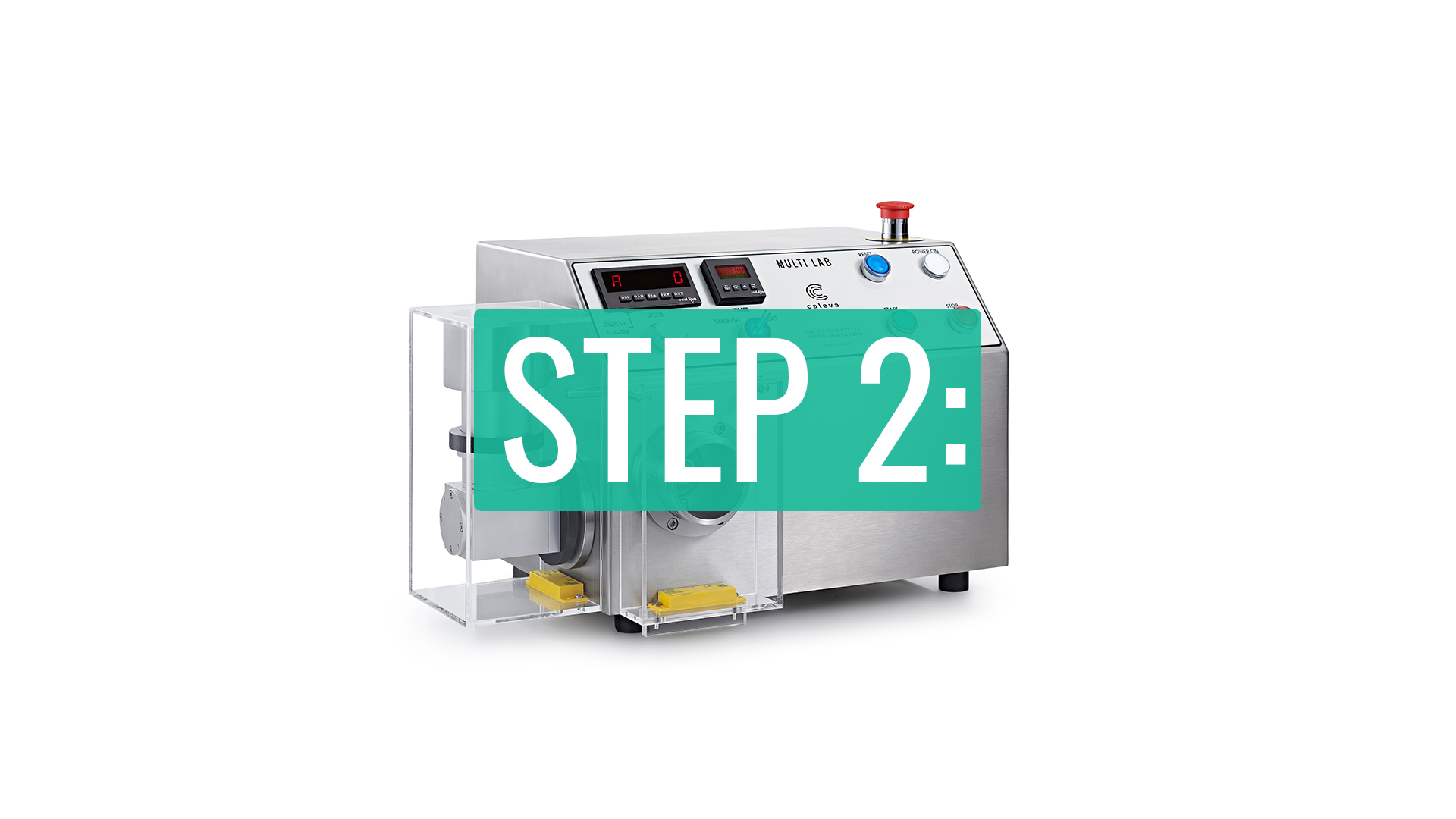

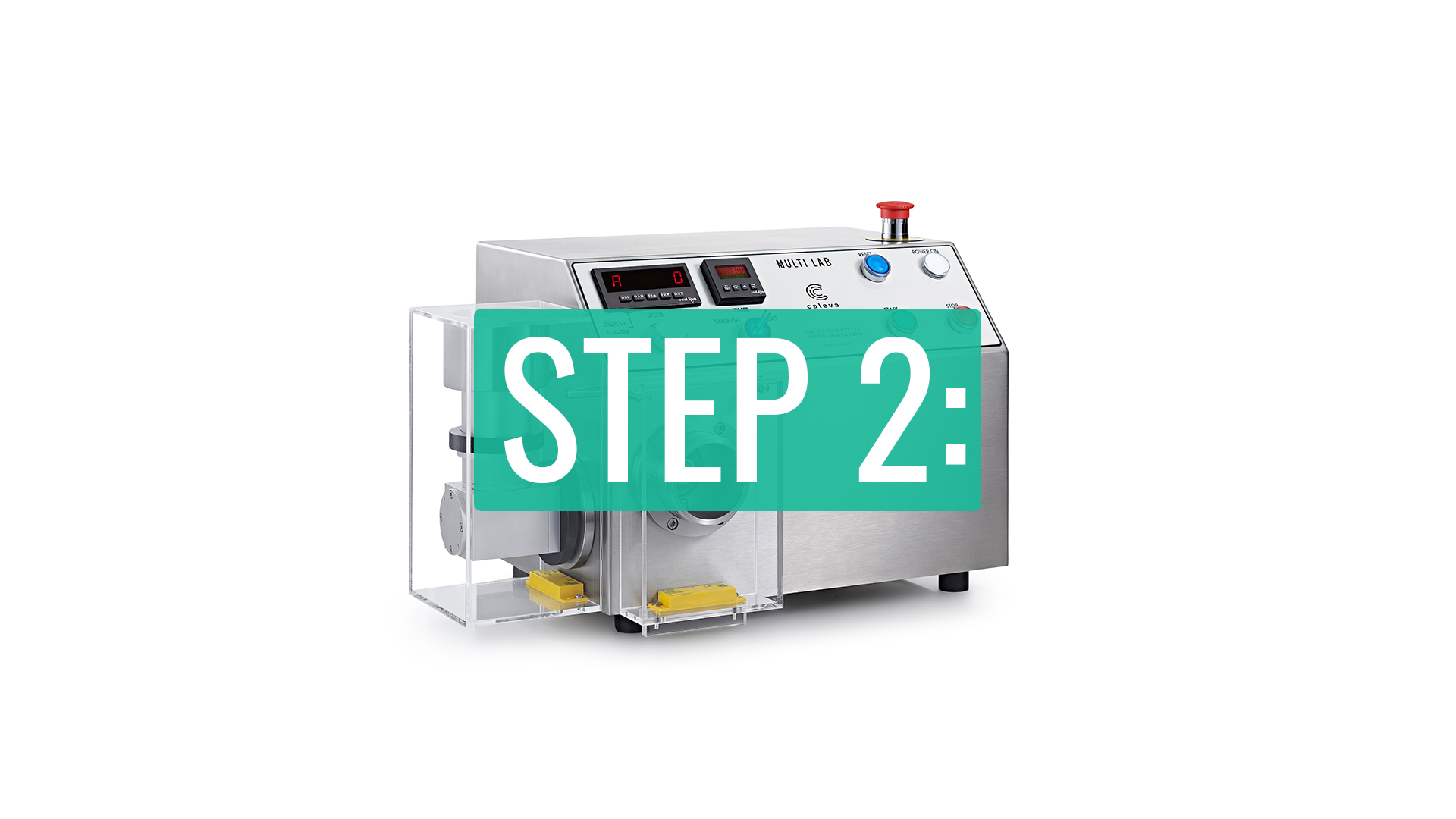

Granulation, Extrusion and Spheronization

Granulation, Extrusion and Spheronization

Complete all 3 stages of this process in under 15 minutes

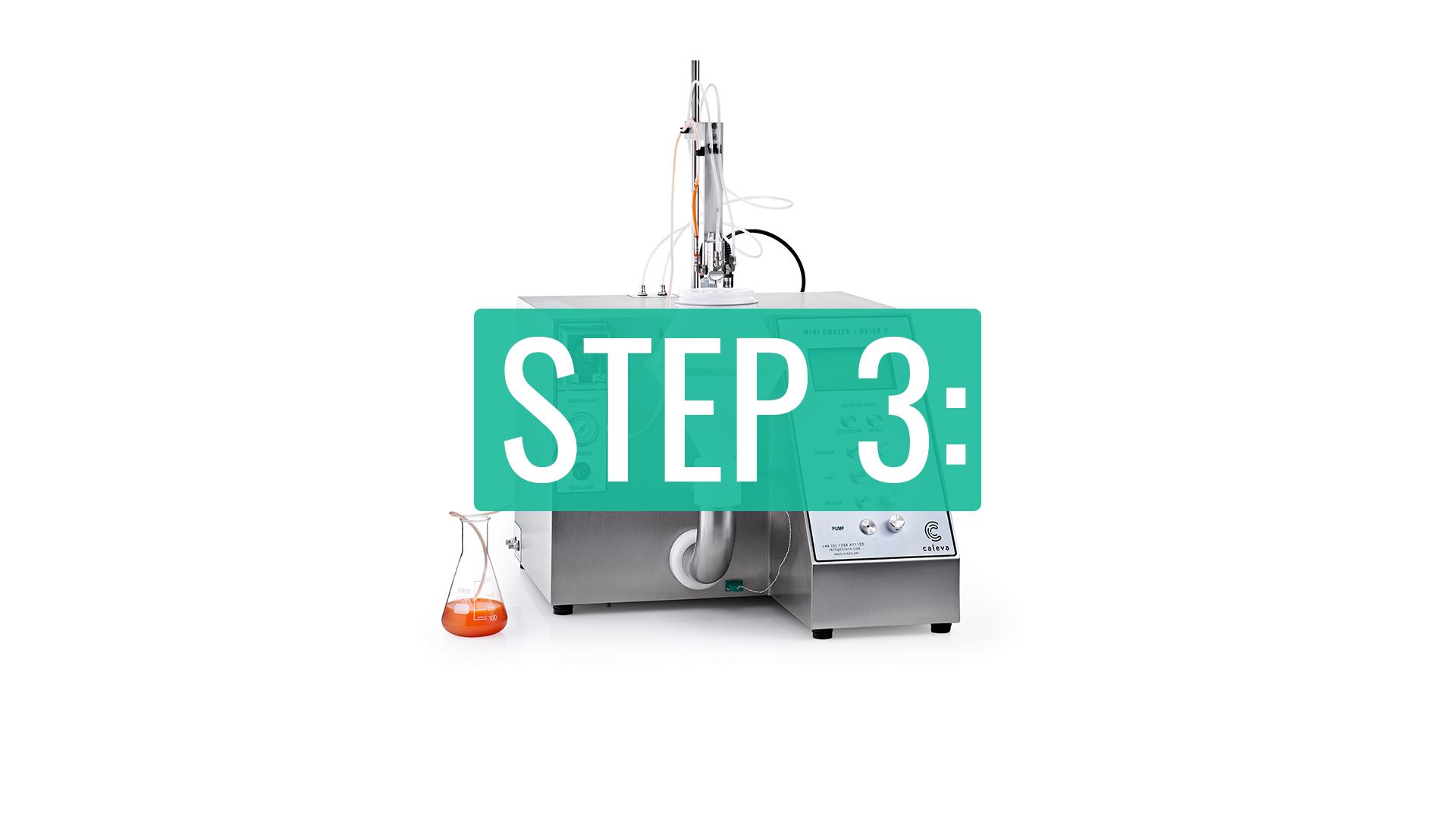

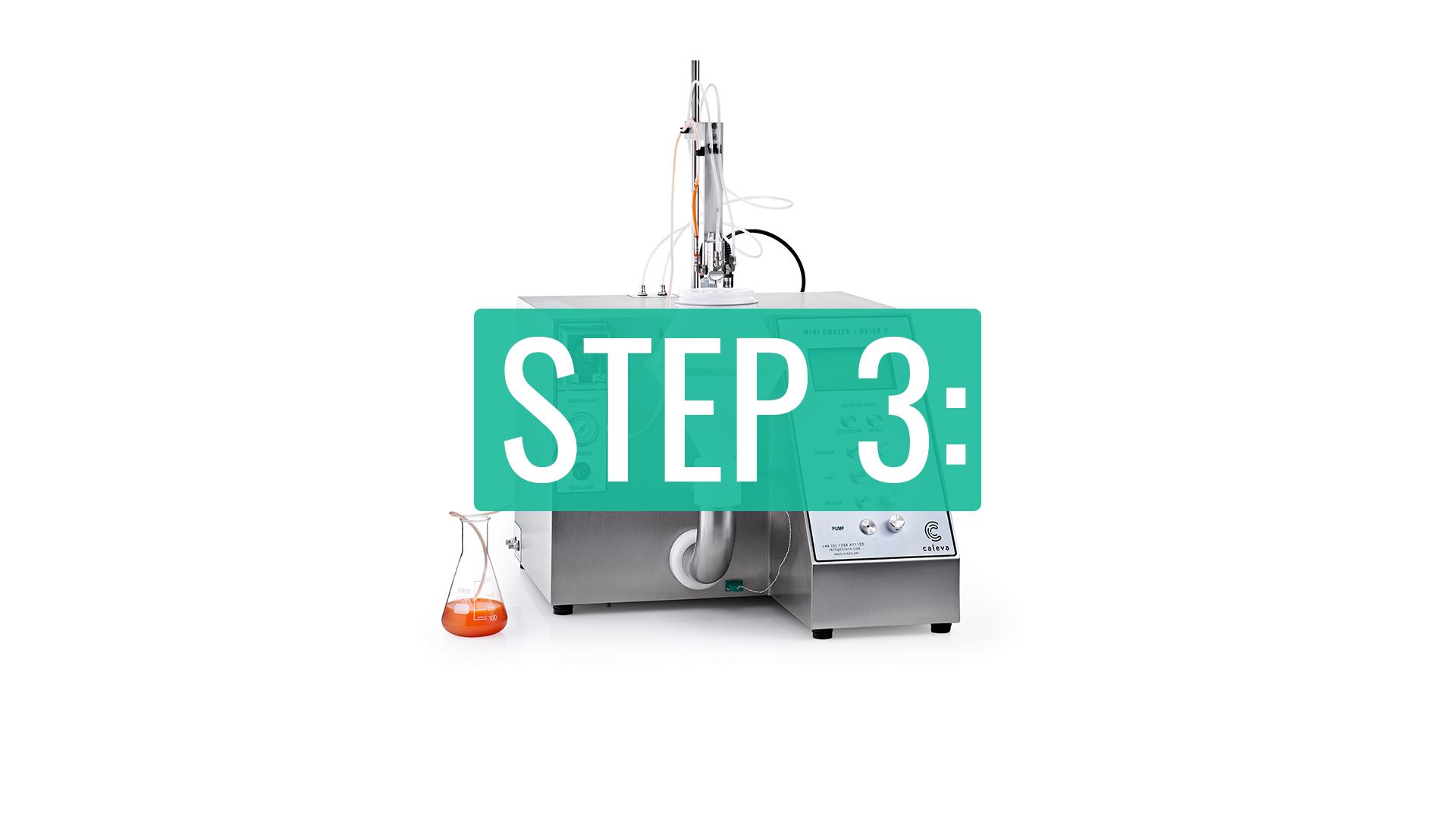

Coating and drying

Coating and drying

Coat from a single tablet up to 150 tablets in a single batch

Start your development cycle with the Caleva Mixer Torque Rheometer (MTR), it is the only repeatable and reliable way to quantify your wet mass to correctly determine the end point of your granulation.

The MTR has established itself amongst multiple major pharmaceutical, catalyst, chemical and other industry leaders as an invaluable tool for formulation development, research and even quality control in a production environment.

The MTR saves you time and money in your formulation development by uniquely providing you with quantitative and reproducible measurements of the rheology of a wet mass, reducing the amount of trial and error work needed to find out how much binder to use, or how long to mix the powders for. These tests save a significant amount of time and often scarce materials.

The information provided by these tests will enable you to optimize your formulations in the shortest possible time. It will enable you to investigate product and excipient quality issues in a quantitative and meaningful way.

For more information on the MTR, click here:

Or if you would like to watch a video on the MTR, click here:

The CML can perform 3 seperate processes: Mixing/Granulation, extrusion and spheronization.

The CML is extremely efficient, often being able to mix, extrude and spheronize a formulation to create pellets in under 15 minutes.

Being capable of performing 3 processes within one machine, the CML saves a lot of benchtop space in the laboratory. In the past, you would need 3 separate pieces of equipment for each stage of the process. The CML, being just larger than an A3 piece of paper, not only reduces your benchtop space requirement, it also increases the time efficiency of your development process due to small contact parts being easy and quick to clean.

There are 2 different sized bowls used for mixing on the CML, one full-sized and one half sized which are interchangeable with the MTR.

Once your formulation is mixed thoroughly (homogenized), using the parameters given to you by the MTR, simply take the mixing attachment off and attach the extruder. The CML extrusion attachment utilises single screw extrusion, and can come with a variety of dies that can be used to help control pellet size, varying from 0.5 mm to 3.0 mm.

Now that you have your extrudate ready, simply attach the spheronizer to the CML and create your pellets.

Just like the CML, the MCD produces results quickly, easily and efficiently.

You can achieve excellent coating uniformity whilst reducing your product cost and wasting very little material. It’s ease of use together with the capability to coat very small batches (from a single tablet or 5g of pellets) makes the MCD an ideal research and development companion for the MTR and CML.

Rheology

Rheology

Quantify the characteristics of your wet mass to correctly determine the end point of your granulation

Start your development cycle with the Caleva Mixer Torque Rheometer (MTR), it is the only repeatable and reliable way to quantify your wet mass to correctly determine the end point of your granulation.

The MTR has established itself amongst multiple major pharmaceutical, catalyst, chemical and other industry leaders as an invaluable tool for formulation development, research and even quality control in a production environment.

The MTR saves you time and money in your formulation development by uniquely providing you with quantitative and reproducible measurements of the rheology of a wet mass, reducing the amount of trial and error work needed to find out how much binder to use, or how long to mix the powders for. These tests save a significant amount of time and often scarce materials.

The information provided by these tests will enable you to optimize your formulations in the shortest possible time. It will enable you to investigate product and excipient quality issues in a quantitative and meaningful way.

For more information on the MTR, click here:

Or if you would like to watch a video on the MTR, click here:

Granulation, Extrusion and Spheronization

Granulation, Extrusion and Spheronization

Complete all 3 stages of this process in under 15 minutes

The CML can perform 3 seperate processes: Mixing/Granulation, extrusion and spheronization.

The CML is extremely efficient, often being able to mix, extrude and spheronize a formulation to create pellets in under 15 minutes.

Being capable of performing 3 processes within one machine, the CML saves a lot of benchtop space in the laboratory. In the past, you would need 3 separate pieces of equipment for each stage of the process. The CML, being just larger than an A3 piece of paper, not only reduces your benchtop space requirement, it also increases the time efficiency of your development process due to small contact parts being easy and quick to clean.

There are 2 different sized bowls used for mixing on the CML, one full-sized and one half sized which are interchangeable with the MTR.

Once your formulation is mixed thoroughly (homogenized), using the parameters given to you by the MTR, simply take the mixing attachment off and attach the extruder. The CML extrusion attachment utilises single screw extrusion, and can come with a variety of dies that can be used to help control pellet size, varying from 0.5 mm to 3.0 mm.

Now that you have your extrudate ready, simply attach the spheronizer to the CML and create your pellets.

Coating and drying

Coating and drying

Coat from a single tablet up to 150 tablets in a single batch

Just like the CML, the MCD produces results quickly, easily and efficiently.

You can achieve excellent coating uniformity whilst reducing your product cost and wasting very little material. It’s ease of use together with the capability to coat very small batches (from a single tablet or 5g of pellets) makes the MCD an ideal research and development companion for the MTR and CML.

Alternatively, send a message to the Online Chat to speak to one of our equipment specialists

Please call us without obligation.

+44 (0) 1258 471122Please call us without obligation.

+44 (0) 1258 471122