Laboratory

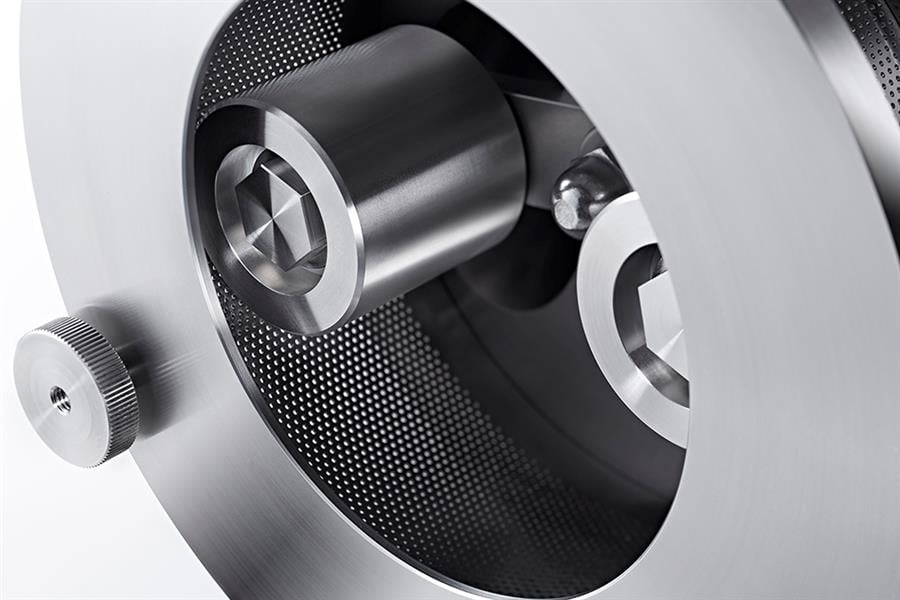

Extruder 20 & Multi Bowl Spheronizer Multi Bowl Spheronization Kit

Extruder and spheronizer with batch size flexibility from 150 g to 1 kg.

The bench-top, low pressure Screen Extruder 20 and the Multi Bowl Spheronizer provides you with the opportunity to work with a wide range of batch sizes.

- The most flexible batch size extrusion and spheronization system for your bench-top

- The Extruder 20 is a low pressure screen extruder, ideal when dealing with softer materials that are sensitive to heat during processing

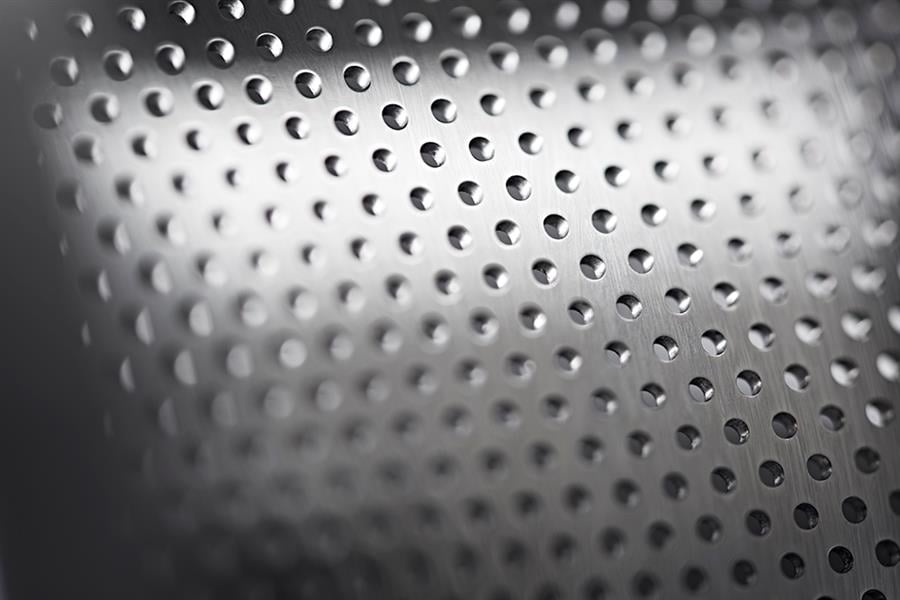

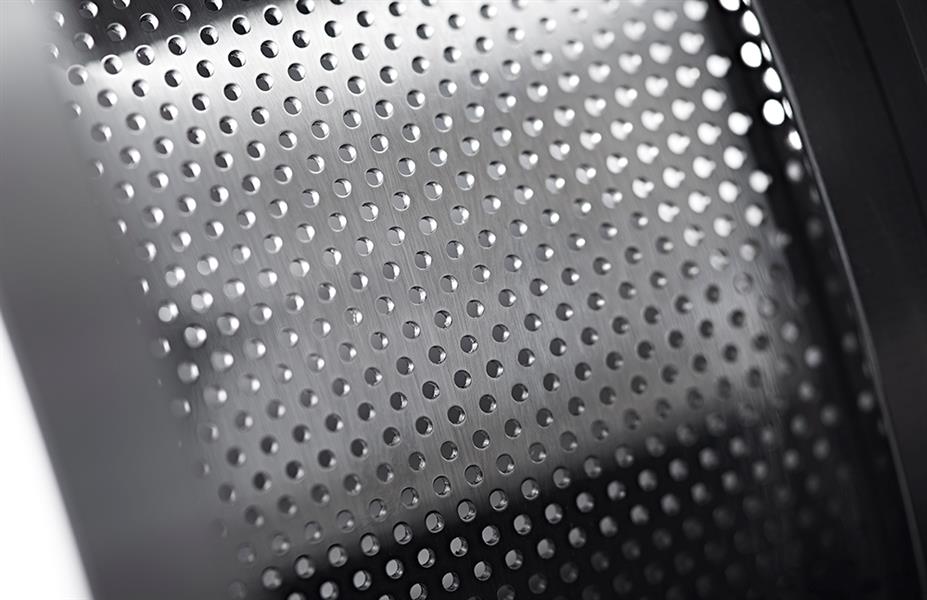

- Full, and half height extrusion screens available

- The Multi Bowl Spheronizer has 4 different sized compatible bowls which can help you understand the scale-up for your formulation

No video selected

Select a video type in the sidebar.

Description

If your research requires you to work with batch sizes between 150 g and 1000 g then the Multi Bowl Spheronization Kit offers you the flexibility you need. The Multi Bowl Spheronization Kit is designed to sit on your laboratory bench-top and includes:-

- The Caleva bench-top screen Extruder 20 with a reduced height or full height screen

- The Caleva Multi Bowl Spheronizer base with a 250 mm, 120 mm, 85 mm or 60 mm diameter bowl

- Reduce your initial investment by choosing only the parts you need, and add to them as your research requires them.

THERE IS NO OTHER LABORATORY SYSTEM DESIGNED TO OFFER THIS WIDE RANGE OF BATCH SIZES

Extruder 20: The low pressure bench-top screen Extruder 20 is available with both full height and reduced height screens to meet the requirements of your chosen batch size.

Multi Bowl Spheronizer: Interchangeable bowls of different sizes can be used to process different batch sizes of pellets. Only one bowl is required at the beginning and this is determined by your preferred batch size.

This low pressure bench-top system is a powerful combination for research, teaching, and product development with batch size flexibility that can be enhanced with additional options if you wish to work with smaller or larger batches.

WHY SHOULD I CHOOSE THIS KIT?

- You will have the option to work with different batch sizes. If your batch size requirements change in the future you have more flexibility, you will save money and you will maximise your development effectiveness

- Low pressure screen extrusion system designed for easy scale up to a cost effective full scale production system

- You control the operational parameters

If you require GMP/GLP?

- Fully compliant with your work involving GLP/GMP when required

- Suitable for food, pharmaceutical, nutraceutical, chemical and other applications

- You have the option of full traceability of contact parts

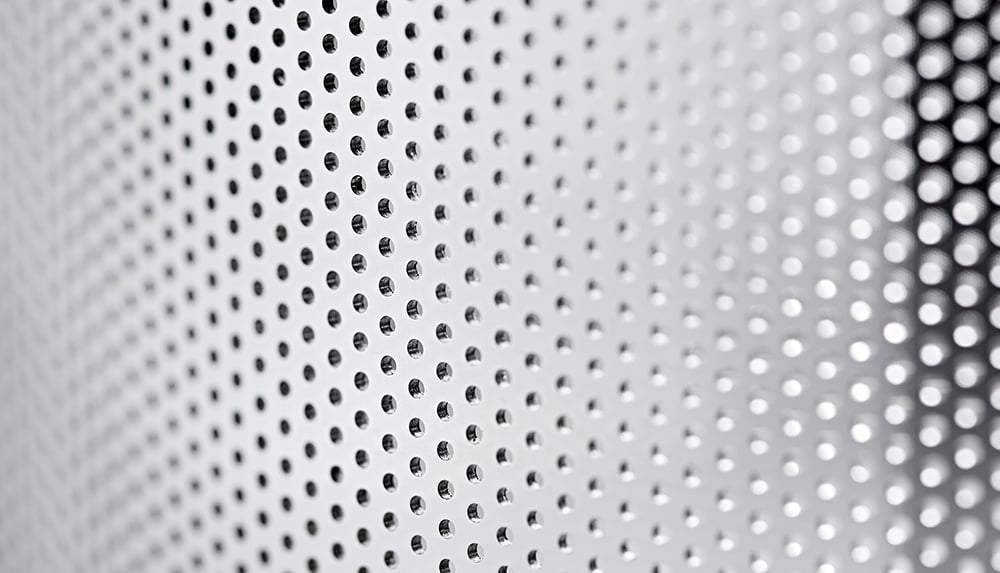

- Product contact parts are 316 or 316L stainless steel or approved plastics

Practical for you

- You can easily and quickly disassemble the equipment for cleaning which results in a rapid turnaround between experiments and batches

Is it safe to use?

- Caleva equipment is designed with safety in mind

- You are safe in the knowledge that you, your operators and your students are safe.

Request a Quote or an Online Demonstration

Contact Caleva

Please call us without obligation.

+44 (0) 1258 471122Contact Caleva

Please call us without obligation.

+44 (0) 1258 471122