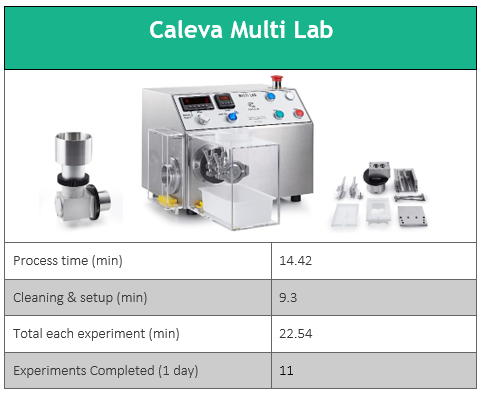

The Caleva Multi Lab (CML) is faster and easier to clean than any comparable bench-top extrusion & spheronization equipment.

This demonstrated advantage can help you to enhance the efficiency of your trial program, offering you the opportunity to increase your chances of success in your research development project and/or teaching program.

We recently had an opportunity to demonstrate this advantage of the Caleva Multi Lab with a new "Spheronization Challenge” at our site in the UK. A new formulation development was tested with different inert excipients and with a range of process variables (including extrudate density) to obtain an optimum pellet with defined characteristics.

The objective was to make (within a single day) an initial assessment and take the best results forward into the next development.

There were a number of possible options to work through and the time allocated to each experiment was limited. During the initial morning trial session, 6 trials were completed and a clear path was proposed for fine tuning in the afternoon. By the end of the day, after 5 more trials, it was possible to make a clear "road map" to guide future activity. Being able to complete 11 separate trials within a single day in the laboratory allowed our customer to return to his own laboratory with a revised view of how effective the CML could be as part of a structured formulation and process development problem.

Increase your chances of a successful result with the CML, reduce your development times by doubling your work rate.

-

Using the Caleva Multi Lab and working together with the customer it was possible to complete 11 trials during one working day, demonstrating a clear proof of concept for the process. By the end of the first morning, a clear and preferred path for the formulation had emerged. In the afternoon session, focusing on fine tuning the preferred formulation and process parameters, a firm follow up proposal was produced. The ability to complete trails iterations quickly comes mostly from the small amount of product required and the much reduced cleaning time required whilst working with the CML. These advantages are clear. The set up and cleaning time for the next trial was considerably less time than any equipment our customer had used before.

-

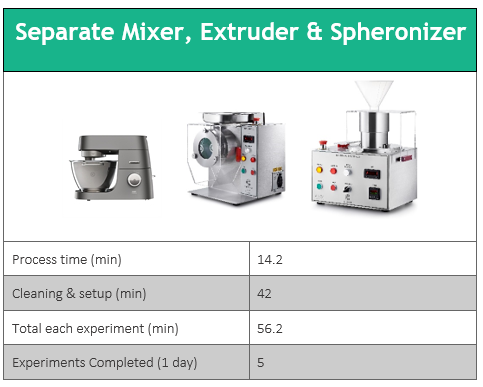

In a typical "industry norm", with separate pieces of equipment for each process, the down-time between each experiment can be as much as 45 and 55 minutes.

-

As results were obtained rapidly, unpromising options could be quickly discarded (thereby reducing time and expense). It was possible to confidently proceed to optimize the most useful process and excipient parameters in further testing.

-

If you have development projects requiring a high number of multiple experiments, then the CML has been demonstrated to offer increased efficiency and cost savings.

Reduce the time it takes to test your formulation by 50%

Laboratory time is costly and the information presented above demonstrates that the Caleva Multi Lab would be able to show a faster return on your investment than traditional laboratory equipment for pellet development. After a recent installation of the Multi Lab at one of Europe’s leading nutraceutical research organisations, the Managing Director and founder wrote to us and said:

Verified Customer -

“What really attracted me to the all-in-one Multi Lab compared to options was the ease and speed of cleaning. We need to frequently switch our project over the course of a typical day to satisfy contract research projects. Using our older, larger and cumbersome equipment we had to spend at least an hour cleaning in between batches and different materials for different projects. We can now carry out a thorough cleaning process in less than half an hour. This has given us increased efficiency and a clear opportunity to offer our research services to a wider base and increased time to allow us to work at a greater level of complexity where this is necessary. I anticipate that I will see a return on my investment within 3 months of taking delivery.”

Interested in increasing your chances of development success?

Contact us using the Online chat in the bottom right of your screen to get instant access to one of our equipment experts.

Or you can use our Contact page to send us an email.

Leave A Comment