The recent European ban of titanium dioxide in Food and Nutraceutical products creates a huge challenge for the industry and raises wider concerns over its potential extension to the pharmaceutical sector. With thousands of pharmaceutical products currently using titanium dioxide in tablet or capsule coatings, the reformulation race is on to identify suitable alternatives.

Knowledge Base

What is the smallest particle that I can coat in the Mini Coater Dryer

The Caleva MCD was originally designed for coating of very small batches of tablets. The original Mini Coater Drier was very efficient at this. However, as a response to several user comments and requests a new version was designed to allow users to also coat small samples of pellets over a range of industries. The original improved design specification that users were requesting was that batches...

Coating large tablets in the Mini Coater Drier

Our general tablet coater literature describes the coating capability of a tablet size of up to 10 mm. However, this refers to a diameter rather than a capsule style design in length. The Mini Coater Drier is incredibly versatile and really the limiting factor is generally a weight issue as opposed to size. It’s important to consider weight/batch size to ensure a good coating motion within the...

Do I need to coat my pellets to prevent disintegration or dissolution?

We have been asked by a manufacturer (interested in looking at the development of Omeprazole formulations) if it was really necessary to coat these pellets with an enteric coating.

Coating pellets and tablets - can results be used in scale up?

We are often asked if parameters used for film coating of materials in the Mini Coater Drier can be used for “scale up” to production. The desire for a process to be scalable is understandable but it is not always feasible or relevant.

A better therapeutic effect with spheroids

In many cases the main reason for the use of pellets in the manufacture of products is for its controlled release properties. However there are reasons to believe that pellets or spheroids in any case can offer a superior therapeutic effect even when modified release is not the prime objective.

How to clean the spray head on your Mini Coater Drier

If you need help in understanding how best to clean the nozzle and spray head to maintain and care for your Mini Coater Drier Tablet & Pellet Coater then this video will show you how. Full instructions are contained in your operating manual. If you require advice or assistance then please contact Caleva and we will be very happy to help.

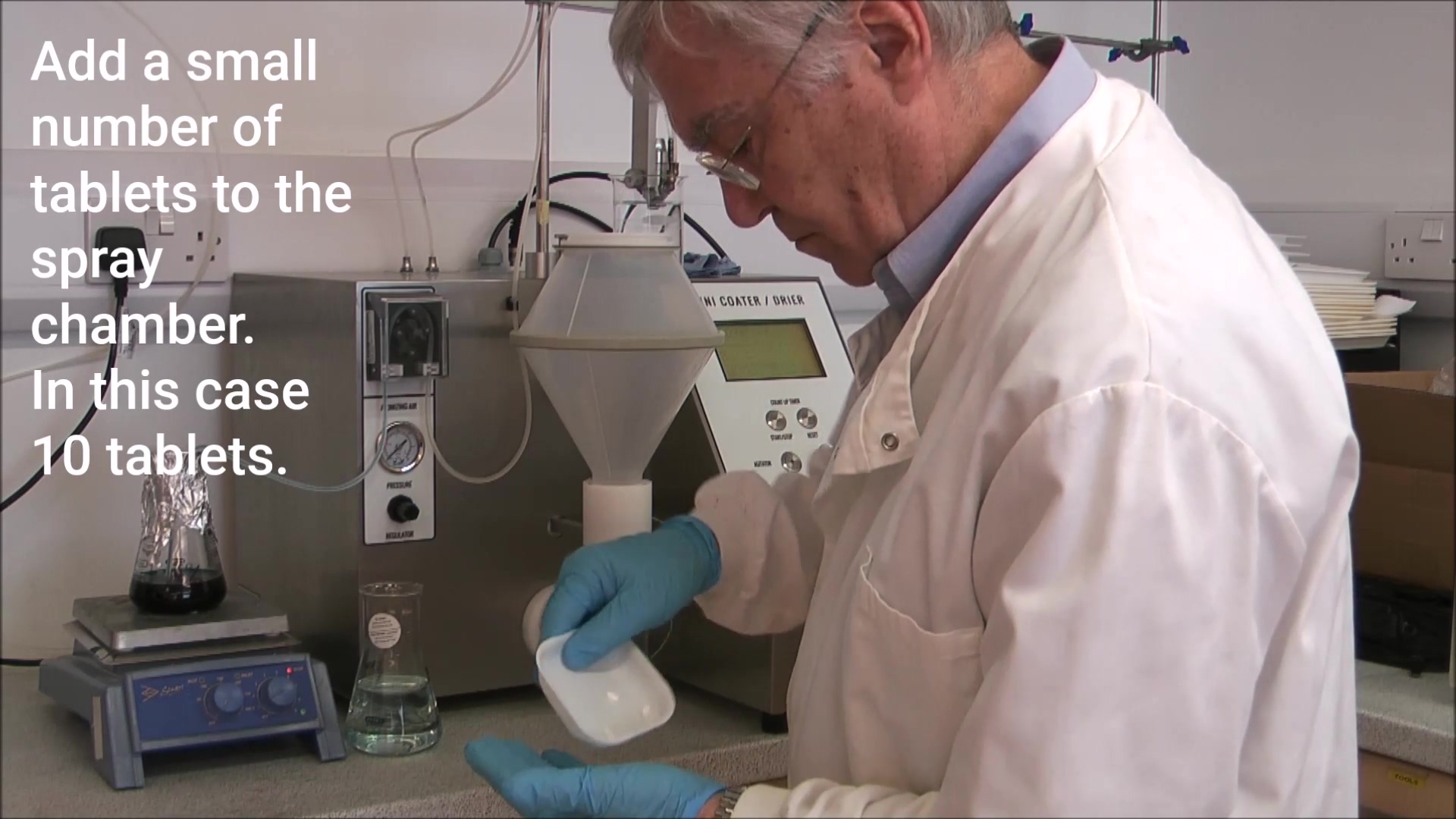

How do I coat tablets or pellets with the Caleva Mini Coater Drier

The Mini Coater Drier (MCD) is an incredibly useful piece of equipment when it comes to coating and drying small batches of tablets or pellets. For a demonstration of the MCD in use, you can watch the video on this page, or for some quick pieces of information on the MCD, check the bullet points below.

- From a single tablet up to about 150 tablets

- From a few grams to about 60 grams of small...

The Caleva Family of Laboratory Equipment

Whilst you may have heard of Caleva and any one of its flagship pieces of equipment, we'd like to introduce you to the family of Caleva laboratory equipment that you may find helpful for your application in your industry sector. Choose one process or choose all of them. Select further functions as you need them. This adaptable and future proof suite of equipment will allow you to obtain proof of...

Coating of very small capsules with the Caleva Mini Coater Drier

The Caleva small tablet and pellet coater is well known for the coating and drying of very small batches of pellets and tablets. It is the only commercially available equipment for this task. The Mini Coater Drier will coat from a single tablet or a few grams of pharmaceutical (or related) pellets. The process was originally developed for pharmaceutical pellet applications, but is also suitable...

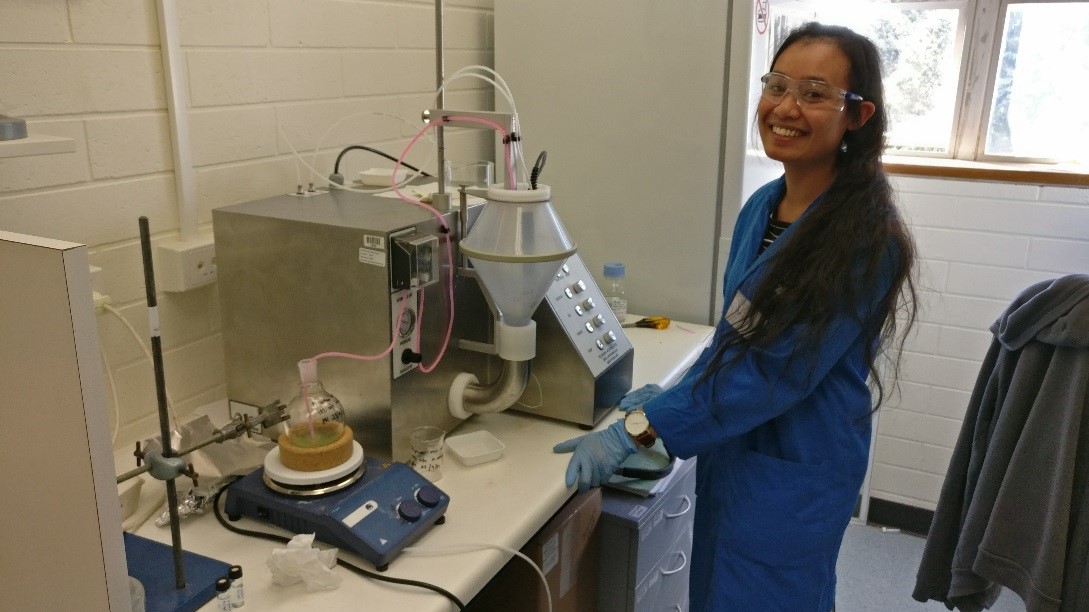

Mini Coater Dryer (air suspension coater) used in formulation development

Tablets were coated with a color overcoat (Aquarius Cool Vanilla BI-1800,Ashland/Aqualon; hydroxypropylmethylcellulose, titanium dioxide, triacetin, polysorbate)using a Caleva air-suspension coater to 2-4% by weight …

Caleva Mini Coater Drier Helps to Reintroduce Endangered Native Australian Animals

Many experts recognise Caleva as a leading manufacturer in extrusion and spheronization equipment for the development of pharmaceutical formulations, catalysts and ceramics. However, the broard scope and flexibility of Caleva equipment provides diverse capabilities that is leading to emerging applications in implant manufacture and conservation science. To explain more, we caught up with Dr Anton...