In the world of pharmaceutical manufacturing, achieving consistently high-quality tablets is a top priority.

Knowledge Base

Measuring and monitoring your formulation

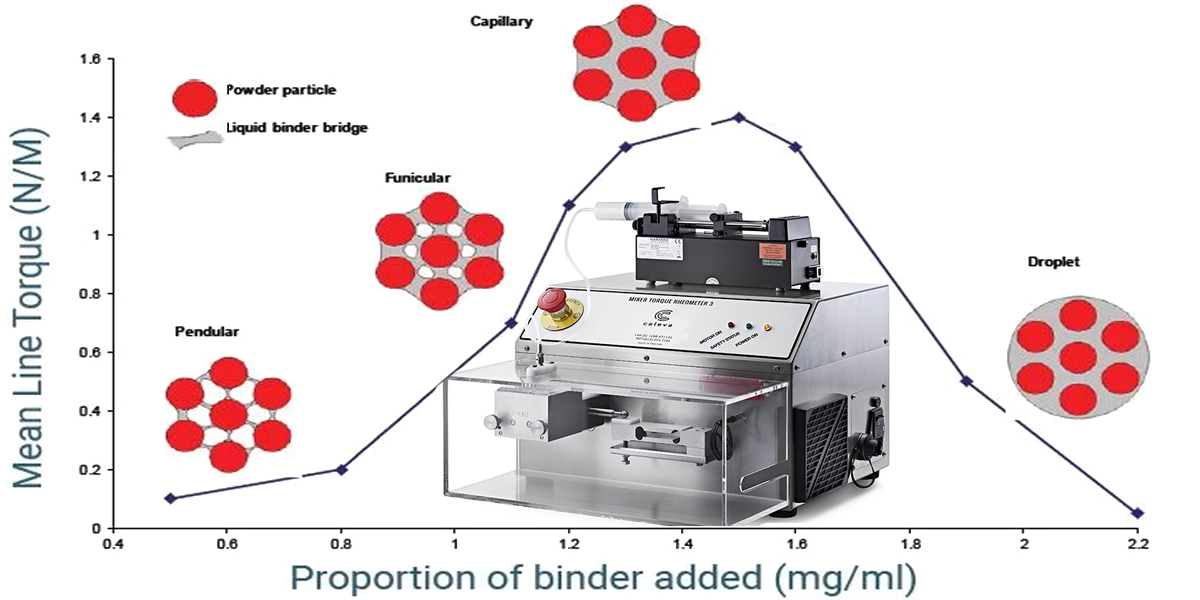

Did you know that the Mixer Torque Rheometer (MTR) is designed to carry out 3 separate experiments essential to your formulation development and production?

Opportunities for Mixer Torque Rheometry

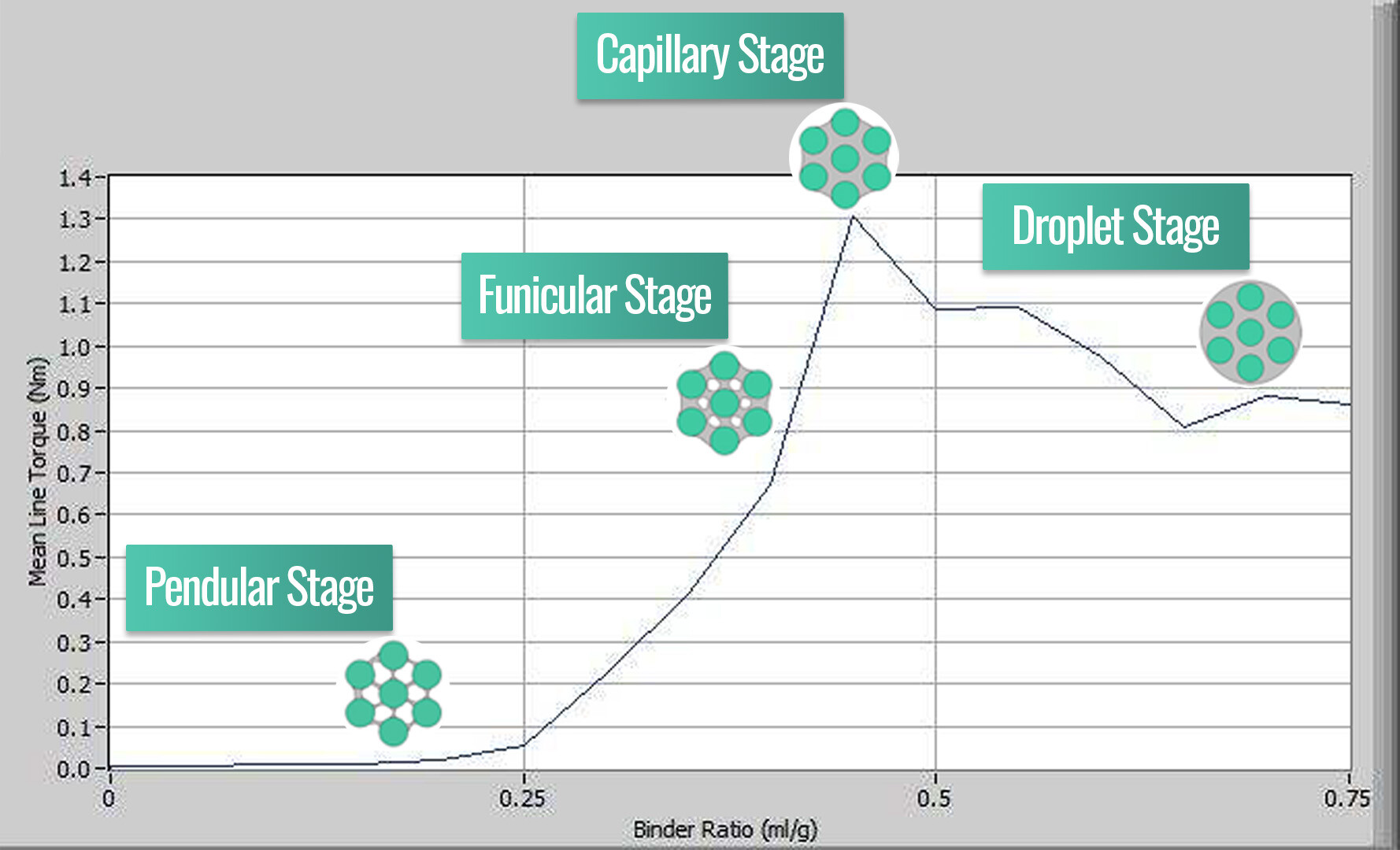

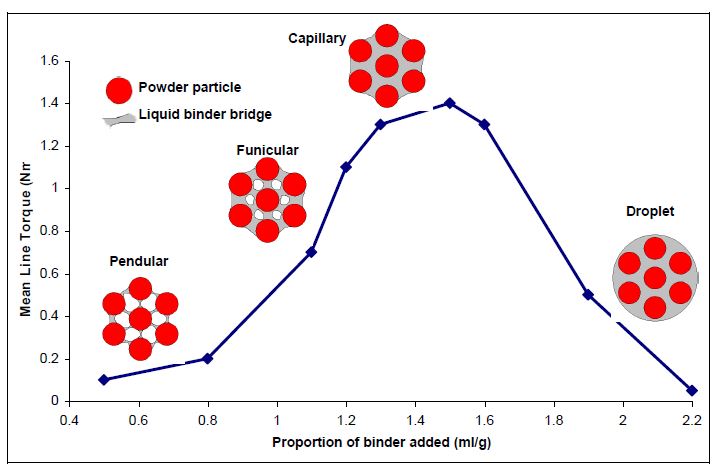

Wet granulations are a useful precursor to many solid dosage formulations and as such are widely used in the pharmaceutical industry. Because of the diverse nature of pharmaceutical materials, granulation is often employed as an intermediate process to enhance flow and compaction properties and improve the final product performance. The properties of a wet granule have a critical effect on the...

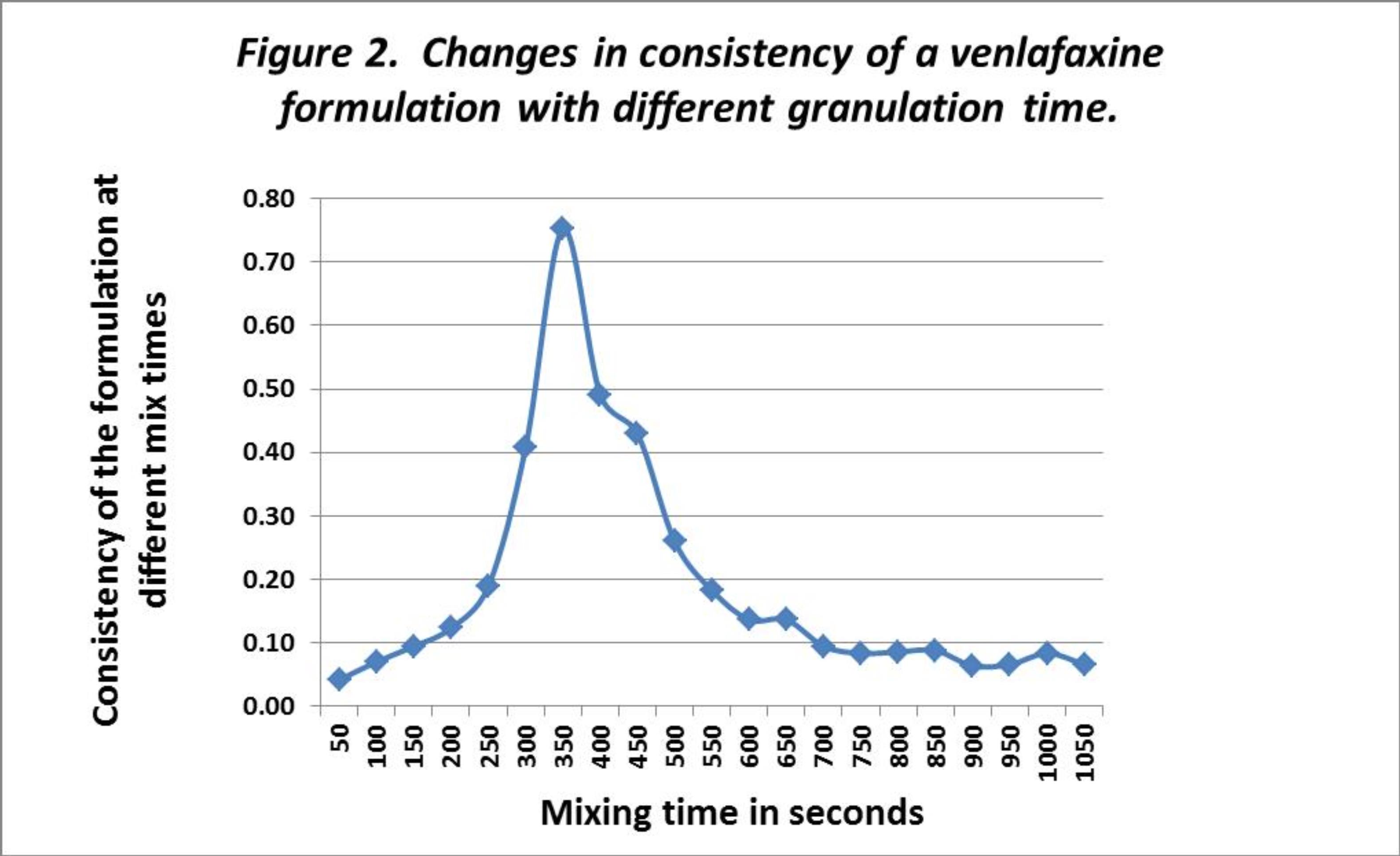

How long should I granulate my materials?

Variable Mix Time Test

It is well-known that a minimum amount of mixing is required to ensure consistent and repeatable product characteristics. What is often less considered is the possibility of over-mixing the product so that the characteristics of the resulting formulation undergo a change.

Rheology methods for the formulation development of tablets

At Caleva we are known for our expertise in helping our customers in the pharmaceutical industry with extrusion, spheronization, and making pellets.But we can also help with tabletting projects !The Caleva Mixer Torque Rheometer (MTR) is widely used to measure the characteristics of a wet granulation to establish the correct endpoint and mix time for any given formulation.The experiments and...