At Caleva, we offer a variety of extruders to meet your needs, from laboratory scale extruders for research and development purposes, to pilot scale extruders and larger models for batch production environments.

Knowledge Base

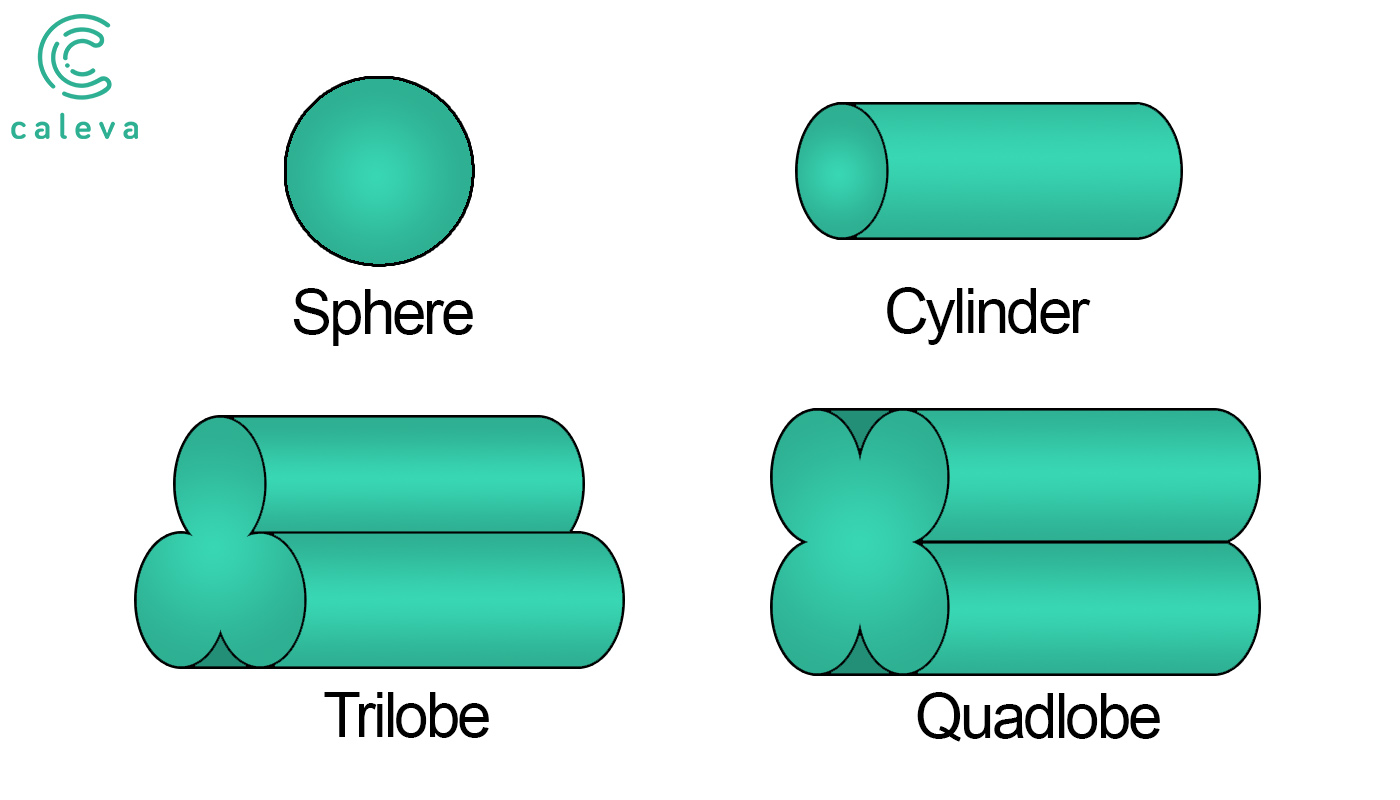

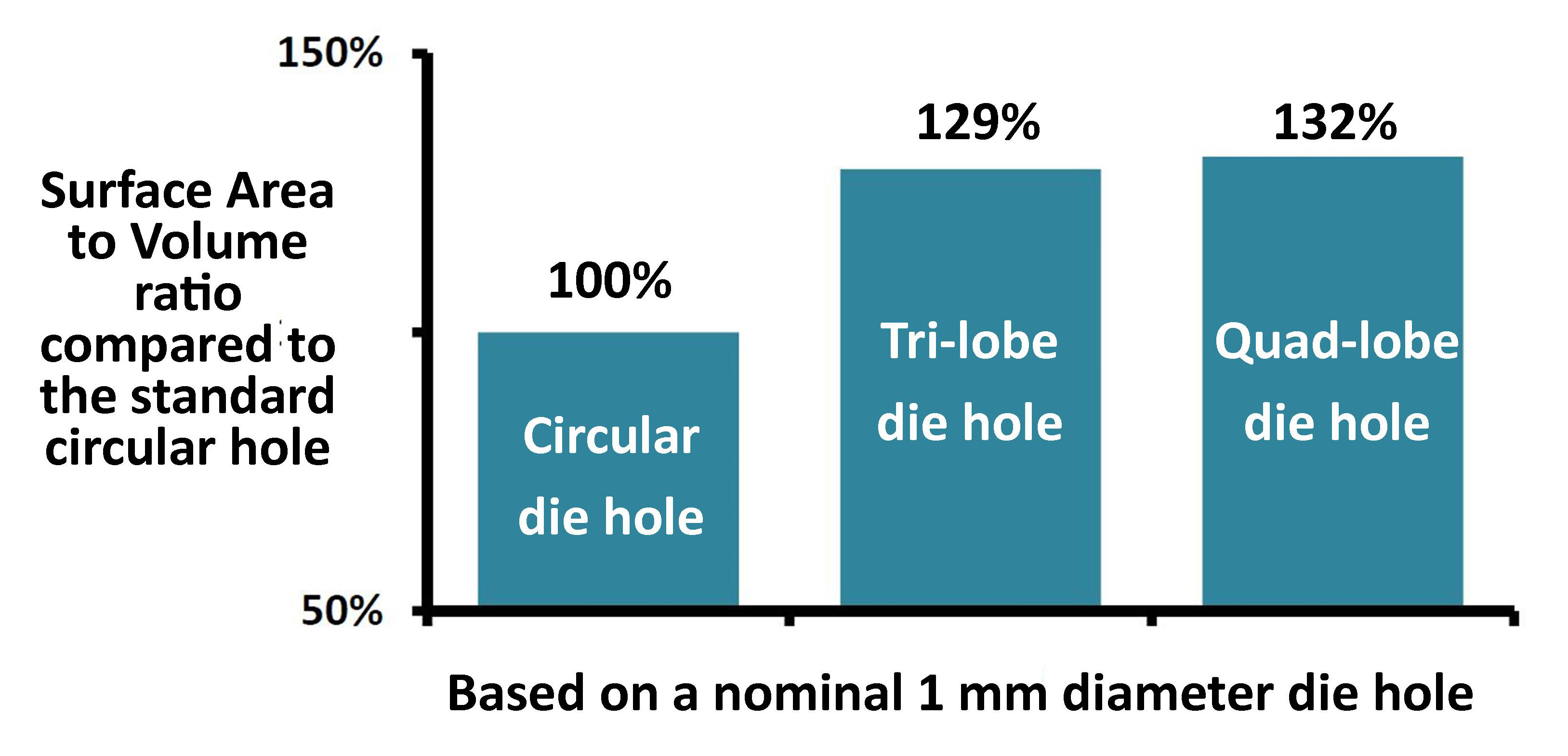

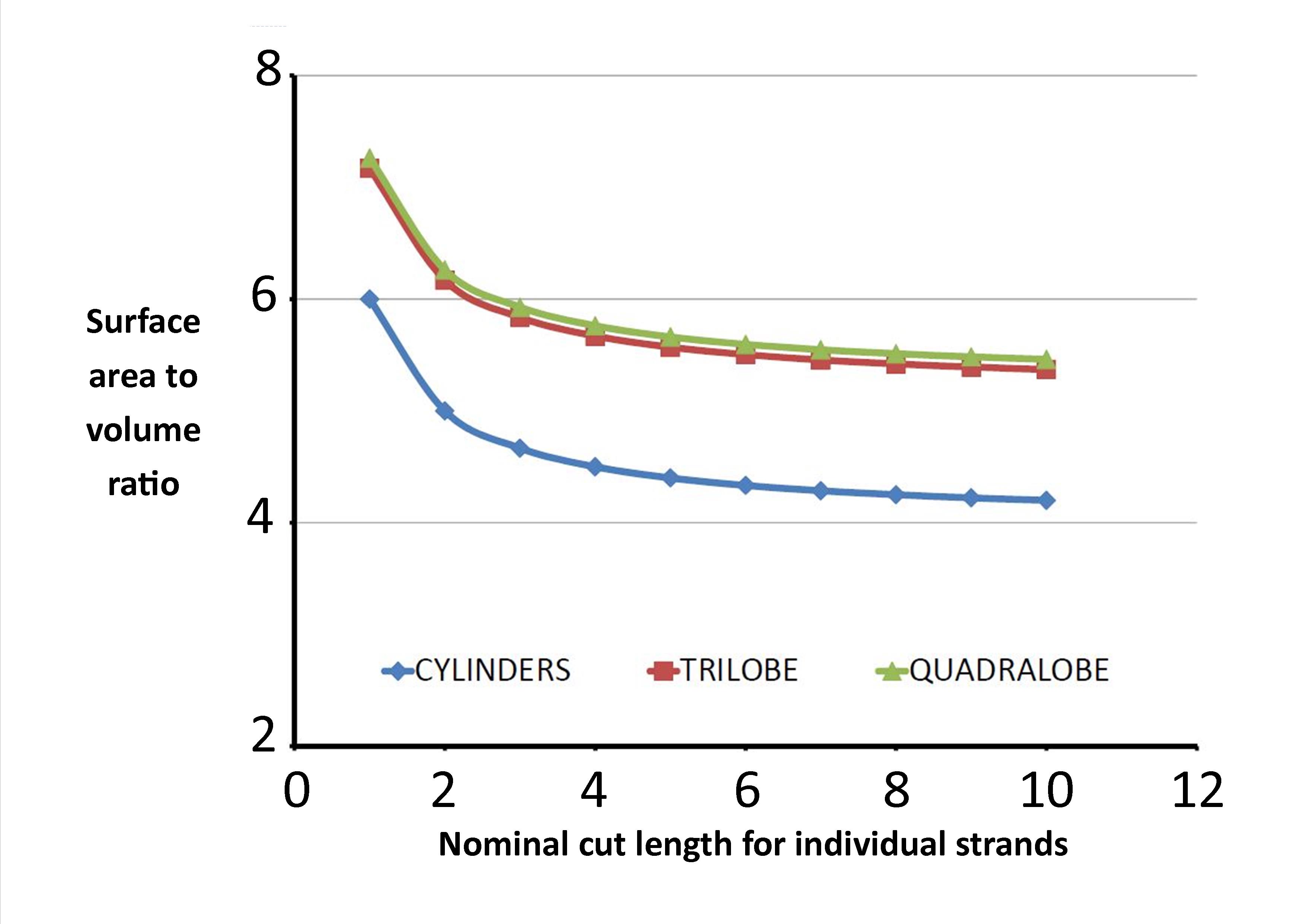

Increase Surface Area of your product with Trilobe and Quadrilobe Dies

An opportunity to shape and form catalyst materials/particles

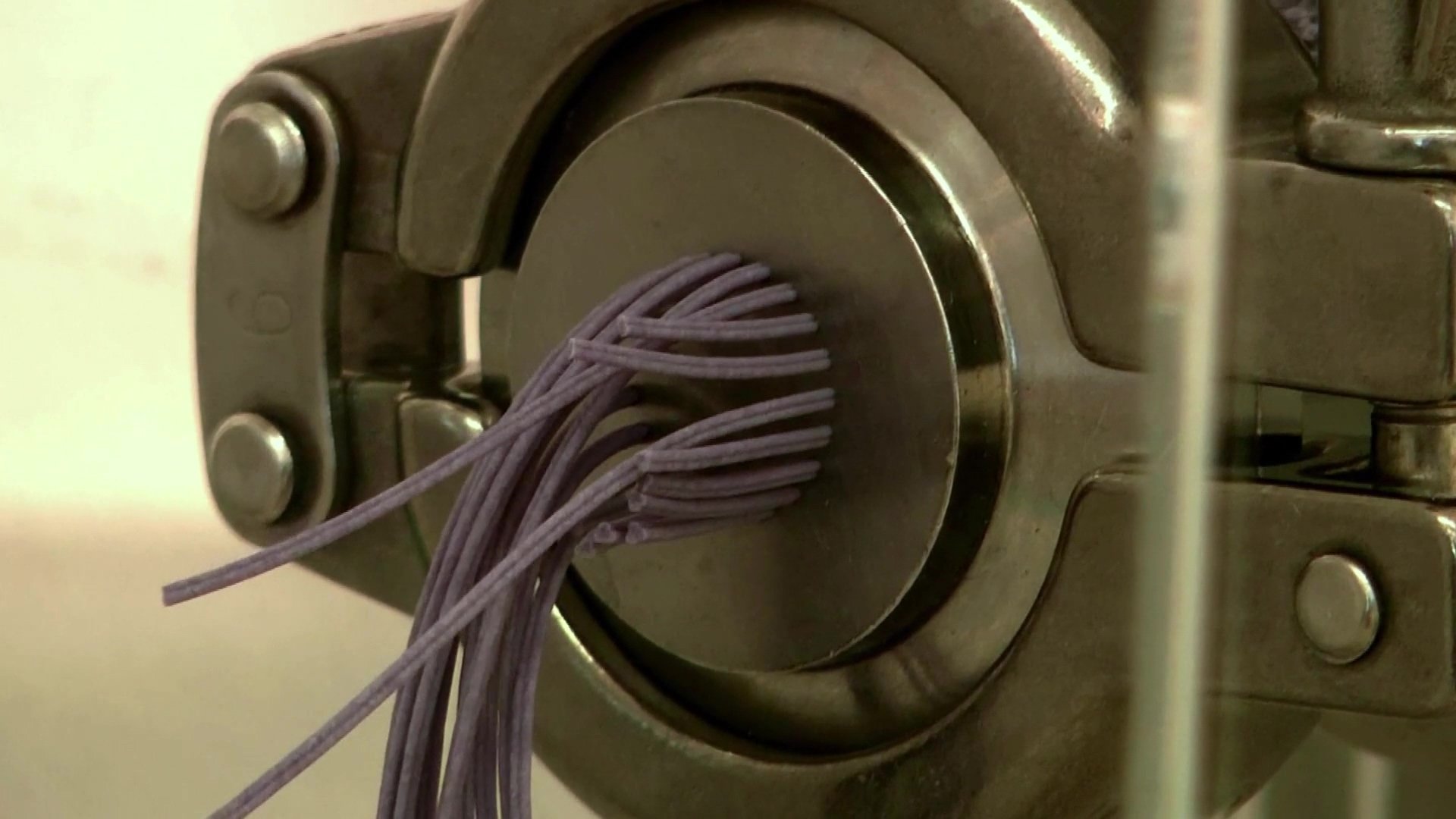

Caleva have had some considerable success with working with the extrusion of small quantities of catalytic material using the Caleva Multi Lab. (the first steps of blending and mixing can also be completed in the same Multi Lab base machine)

Shaped Catalyst Body Preparation with MTR and Caleva Screw Extruder

Shaped Catalyst Body Preparation. Zeolite HZSM-5 (ACS Materials, M38) was mixed as a dry powder with alumina (Sasol, Catapal D (Boehmite)) and the required amount of Milli-Q water to ensure an optimum solid-to-liquid ratio for extrusion (measured using a Mixer Torque Rheometer, Caleva). The paste, containing a ratio of 70:30 wt % zeolite:binder, was extruded using a Mini-Screw Extruder (Caleva),...

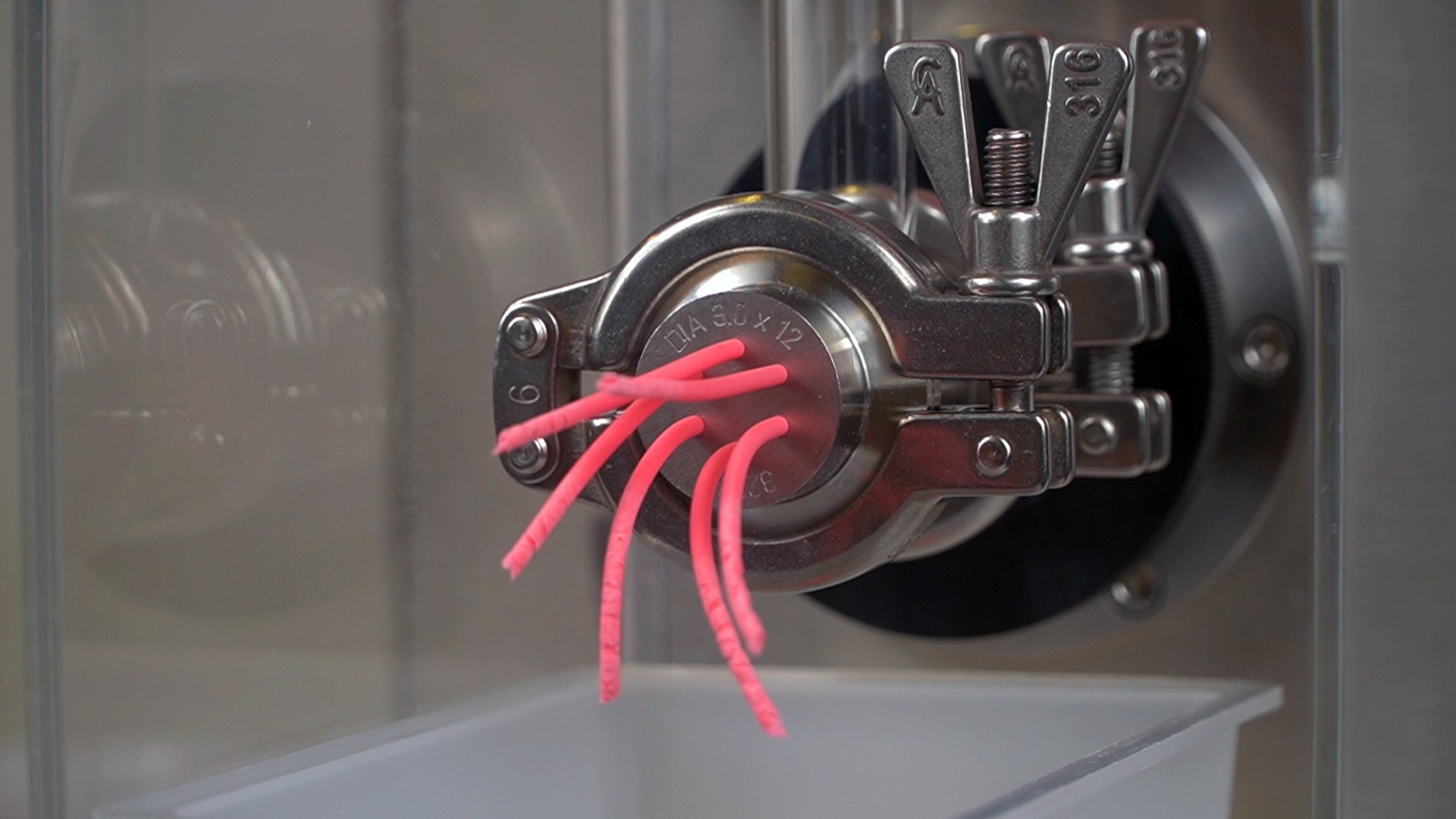

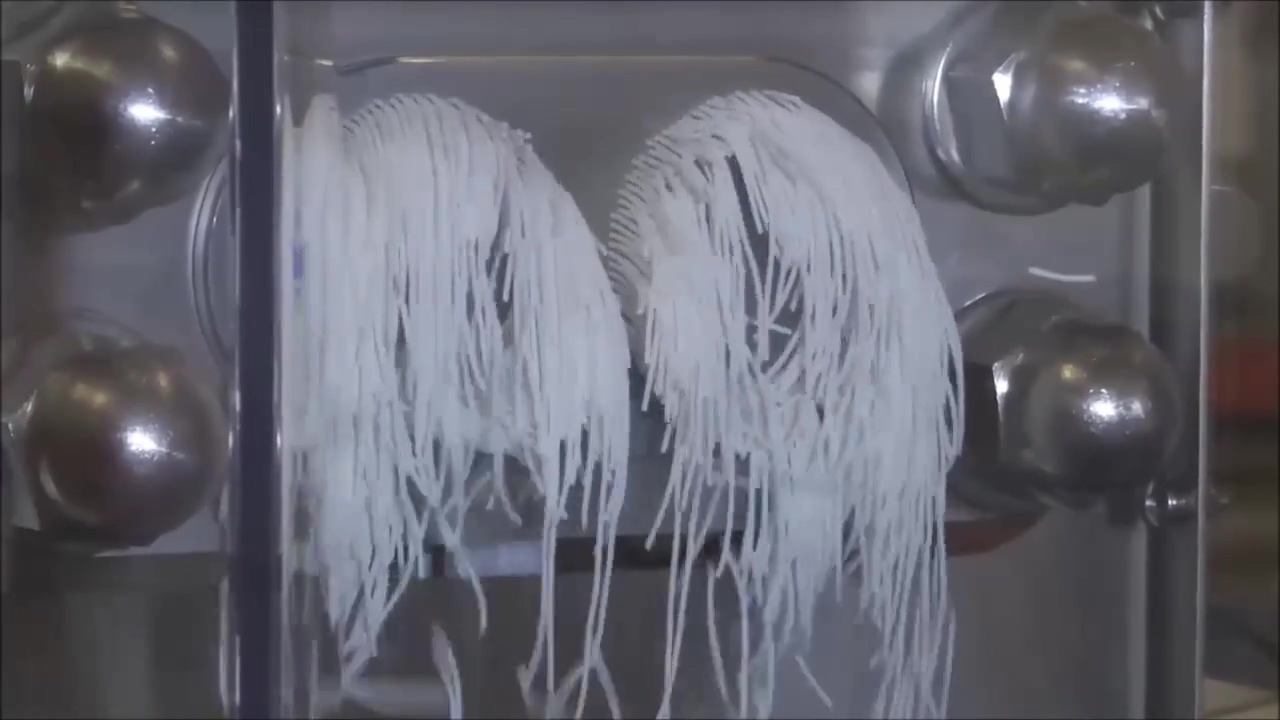

Extrusion of small batches

The Caleva Multi-Lab (CML) can Mix/Granulate, Extrude and Spheronize all in one base unit.

This article is about the Extruder attachment that comes with the CML.

The Multi-lab is capable of working with a variety of materials from catalysts and pharmaceuticals, to agricultural products.

The Extruder

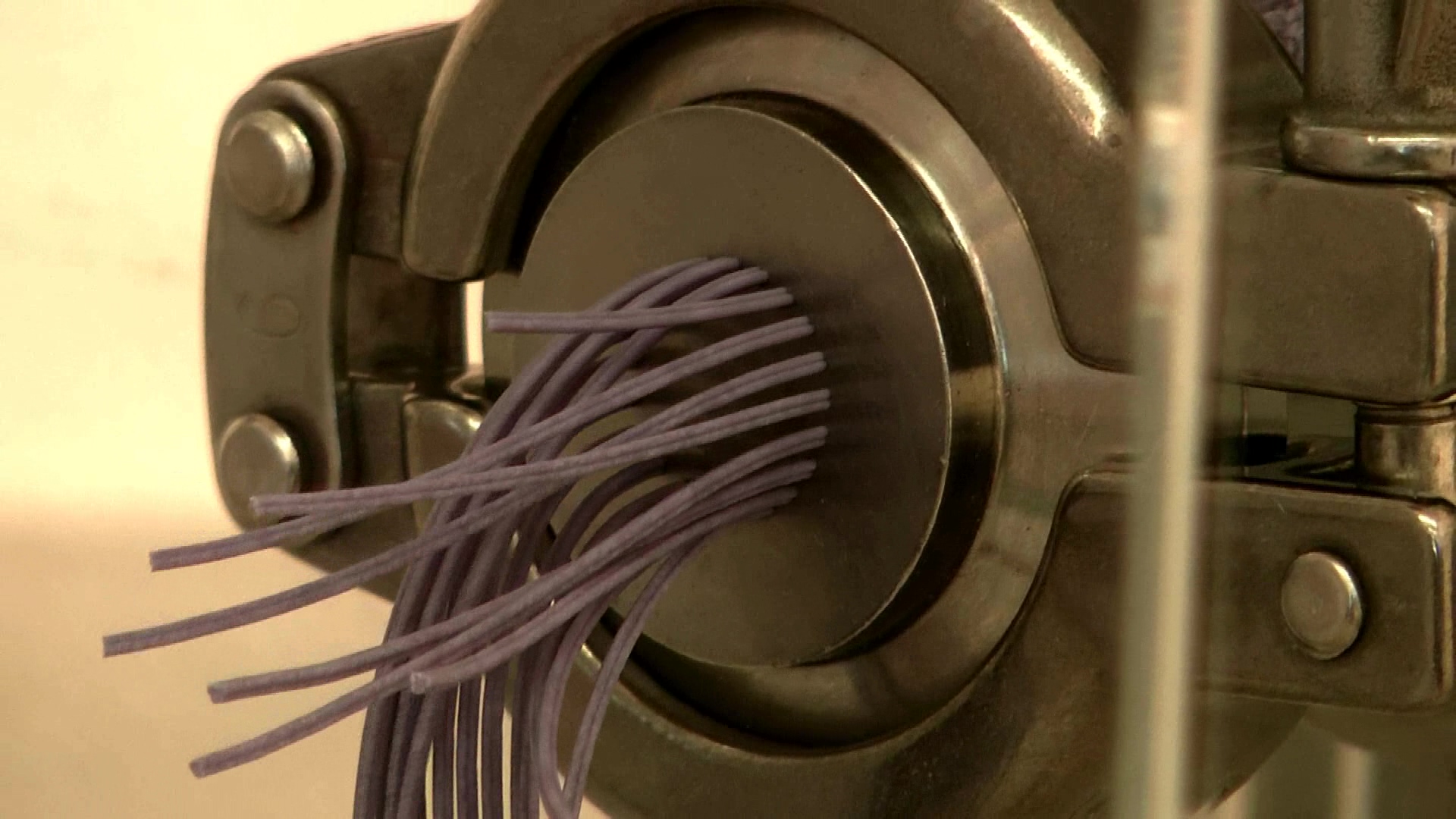

The extrusion attachment on the CML is in the form of a single screw extruder. A variety of dies...

Extruder dies | all sizes | variable density | quadrilobe | trilobe

In the process of extrusion, having different dies available to process your product is key to increasing your chances of development success. This is why we offer a large range of dies to help you find the best options for your formulation.

We offer die plates that are excellent for most uses, like our 1 x 1 mm die, however sometimes a more specialist die may be needed. Our trilobe and...

Extrusion of catalyst and petrochemical materials

An opportunity in laboratory extrusion with catalyst material. We have recently had some considerable success with one of our customers working with the extrusion of small quantities of catalytic material.

Extruding catalyst materials for petrochemical and adsorption products

Using the Caleva Multi Lab it is possible to extrude of small quantities of catalytic material, whilst increasing the surface area to volume ratio of the extrudate produced.

Guide to the optimum diameter to length ratio of extrudate fragments

Is there a guide to the optimum Length to Diameter ratio of the extrudate fragments?

In the calculations used to demonstrate the data it is assumed that the extrudate is an infinitely long strand. In this case the length of the extrudate has no influence on the data shown. In reality, extrudate is not infinitely long and as the individual strands of the extrudate produced become shorter, the...

What type of pharmaceutical or catalyst extruder do I need?

All extrusion processes require the generation of pressure within the material to be extruded. When materials are put under pressure heat is generated. This cannot be avoided but different extrusion types generate different amounts of heat. There are basically three different types of extruder and the one chosen may have far reaching implications on production operations. It is important that the...

Formulation development of catalyst materials zeolite and bentonite?

We always offer our potential users the opportunity to test their formulation with us in our lab. This is to ensure that installing our machines would be the right decision for their formulation development, and/or their production environment.

This short article has been written from notes that Dr Steve Robinson made during trials with catalysts sent to us by a customer and we achieved some...

Trilobe and quadrilobe extruder dies with catalyst adsorption

Can trilobe and quadrilobe extruder dies provide benefits when working with catalysts or products for gas adsorption?

Caleva Mixer working in catalyst application for Ethylene and Propylene

Components were mixed with a specialist Caleva mixer to form a homogeneous paste

Catalyst Pellets cracked! The strange apple sauce method

Over the past couple of years I have worked with a huge number of chemical engineering teams, trying to crack the optimum base for a catalyst pellet. After hours of trials and research, I am pleased to say, we’ve done it!