Thanks to Caleva not only for making great equipment but also for being helpful to give us access to it within our budget. I would ALSO like to thank Caleva for the help given in providing the small scale extrusion and spheronization equipment for our laboratory. The latest research paper from our pharmaceutical department (Lipids bearing extruded-spheronized pellets for extended release of...

Knowledge Base

Mini Coater Dryer (air suspension coater) used in formulation development

Tablets were coated with a color overcoat (Aquarius Cool Vanilla BI-1800,Ashland/Aqualon; hydroxypropylmethylcellulose, titanium dioxide, triacetin, polysorbate)using a Caleva air-suspension coater to 2-4% by weight …

Caleva Mixer working in catalyst application for Ethylene and Propylene

Components were mixed with a specialist Caleva mixer to form a homogeneous paste

Agglomeration properties of gluten-free flours under water addition and shearing conditions

The different states of agglomeration were identified by the evolution of rheological properties under water addition and shearing conditions using a Caleva®mixer torque rheometer.

Caleva Mini Coater Drier Helps to Reintroduce Endangered Native Australian Animals

Many experts recognise Caleva as a leading manufacturer in extrusion and spheronization equipment for the development of pharmaceutical formulations, catalysts and ceramics. However, the broard scope and flexibility of Caleva equipment provides diverse capabilities that is leading to emerging applications in implant manufacture and conservation science. To explain more, we caught up with Dr Anton...

How can I be sure that the trials and development work that I do will give me comparable results when I need to scale up to production sizes?

- The smallest extruder we offer is the Caleva Multi Lab (CML) with an extruder attachment designed to work with...

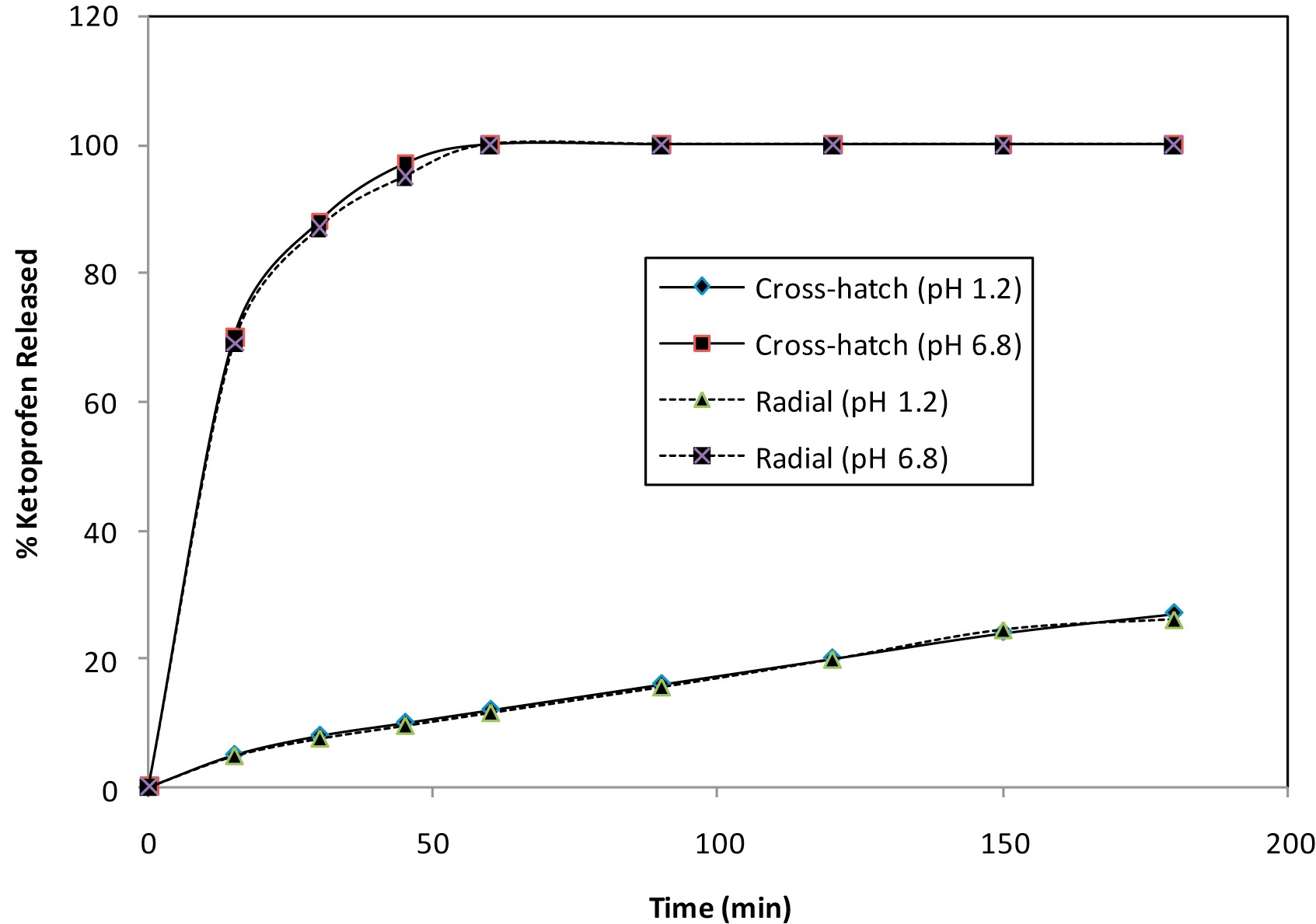

Effect of spheronizer plate design on the spheronization of ketoprofen

Abstract: Spheronization is a rapid process for production of microspheres. The process involves the dry mixing of drug with microcrystalline cellulose (MCC), which on subsequent wetting with water forms a plastic mass suitable for extrusion and spheronization. As in any pharmaceutical operation, large number of factors may affect the production of pellets, which can be related to formulation or...

Extrusion–spheronization a promising pelletization technique: In-depth review

Abstract

This review article deals with various aspects of the extrusion–spheronization technique. The first part includes different steps in the production process of pellets such as granulation, extrusion, spheronization, and drying. In the second part, the parameters which can influence the quality of pellets including formulation (moisture content, granulating liquid,excipients, and...

Spheronized Pellets | Extended Release | Poorly Soluble Antiemetic Agent

Thanks to Caleva not only for making great equipment but also for being helpful to give us access to it within our budget. I would ALSO like to thank Caleva for the help given in providing the small scale extrusion and spheronization equipment for our laboratory. The latest research paper from our pharmaceutical department (Lipids bearing extruded-spheronized pellets for extended release of...

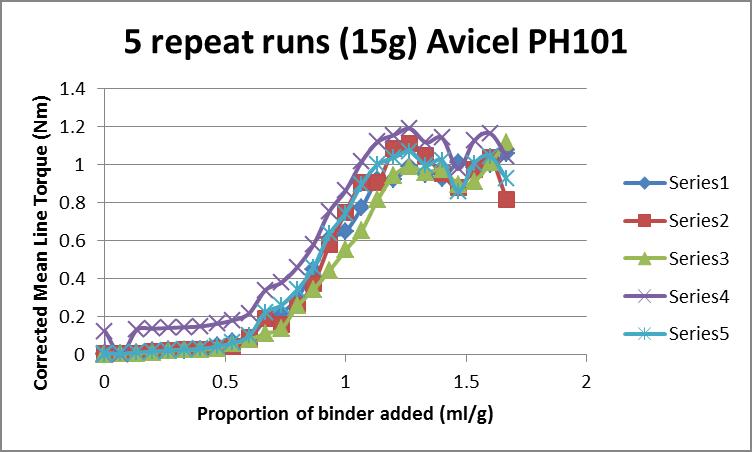

How reproducible can measurements be of something that is not homogeneous?

The MTR-3 uniquely offers a means of characterising the rheological properties of a wet granulation by providing a quantitative value of the consistency of the material tested. The more traditional hand squeeze test, previously widely used, to measure or compare granulations, is falling into disrepute and is no longer considered appropriate for modern day industrial production or research...

Yield Problems in Production and Quality Control

One of the strengths of the Caleva Mixer Torque Rheometer (MTR-3) is that it can be used to verify the properties of wet powder mass samples taken during production in large scale mixer/granulator systems.

How the Mixer Torque Rheometer resolved a tablet friability issue

Caleva worked closely with a well known producer of food supplements made from natural materials, plant extracts and other natural food sources. Their tablet formulations work well and this nutraceutical company has a good reputation for their products. Generally they do not encounter problems with tablets breaking or disintegrating during manufacture, packing or storage.

Determination of moisture requirement to prepare spheroids by extrusion-spheronization

Spheroids are popularly used in the design of multi-particulate drug delivery systems. Extrusion and spheronization is commonly employed to manufacture spheroids in the pharmaceutical industry. It is a multiple-step manufacturing process which could be summarized into the flow chart as shown in Figure 1.

Save Time and Cost in Formulation Development

In the mid 1990’s, the field of pyrotechnics was limited mainly to applications in aircraft ordnance, fireworks and rock blasting. This has been developed to a highly advanced science and is an extensively used technology which finds application in spacecraft, aircraft and underwater vehicle systems. “Pyrotechnic “is defined as “explosive-actuated” and refers especially to devices in which...

End Point Determination Using the Caleva Mixer Torque Rheometer

A company wished to move a formulation currently undergoing product development from small scale laboratory (with batches of 50 grams) to the next stage for a larger scale batch trial of 100 kg (scale–up). The development had been started using a small Caleva Multi Lab bench top mixer (maximum batch capacity 50 gram of wet mass). This development had been successful and now additional samples...

Do you have heat generation issues with your extrusion process?

During production scale extrusion heat is generated as a result of the process. The amount of heat generated will vary depending on:

- The formulation of the product

- The rate of extrusion

- The physical specifications of the extruder

- The type of extruder being used, for example, screw, gear, or basket.

Catalyst Pellets cracked! The strange apple sauce method

Over the past couple of years I have worked with a huge number of chemical engineering teams, trying to crack the optimum base for a catalyst pellet. After hours of trials and research, I am pleased to say, we’ve done it!

Spheronization Barrier Technique from Caleva

OK, so this was a tip I discovered a while back, but now it’s becoming more and more beneficial for me in practice when working with sticky, viscous materials. Perhaps this will help you too?

The importance of mixing time for formulation development

It is well established and understood that one of the most important factors in the development of a formulation for both tableting and making pellets by extrusion and spheronization is the amount of liquid binder added to the formulation. What is less widely acknowledged is the importance of mixing and the mixing regime used.