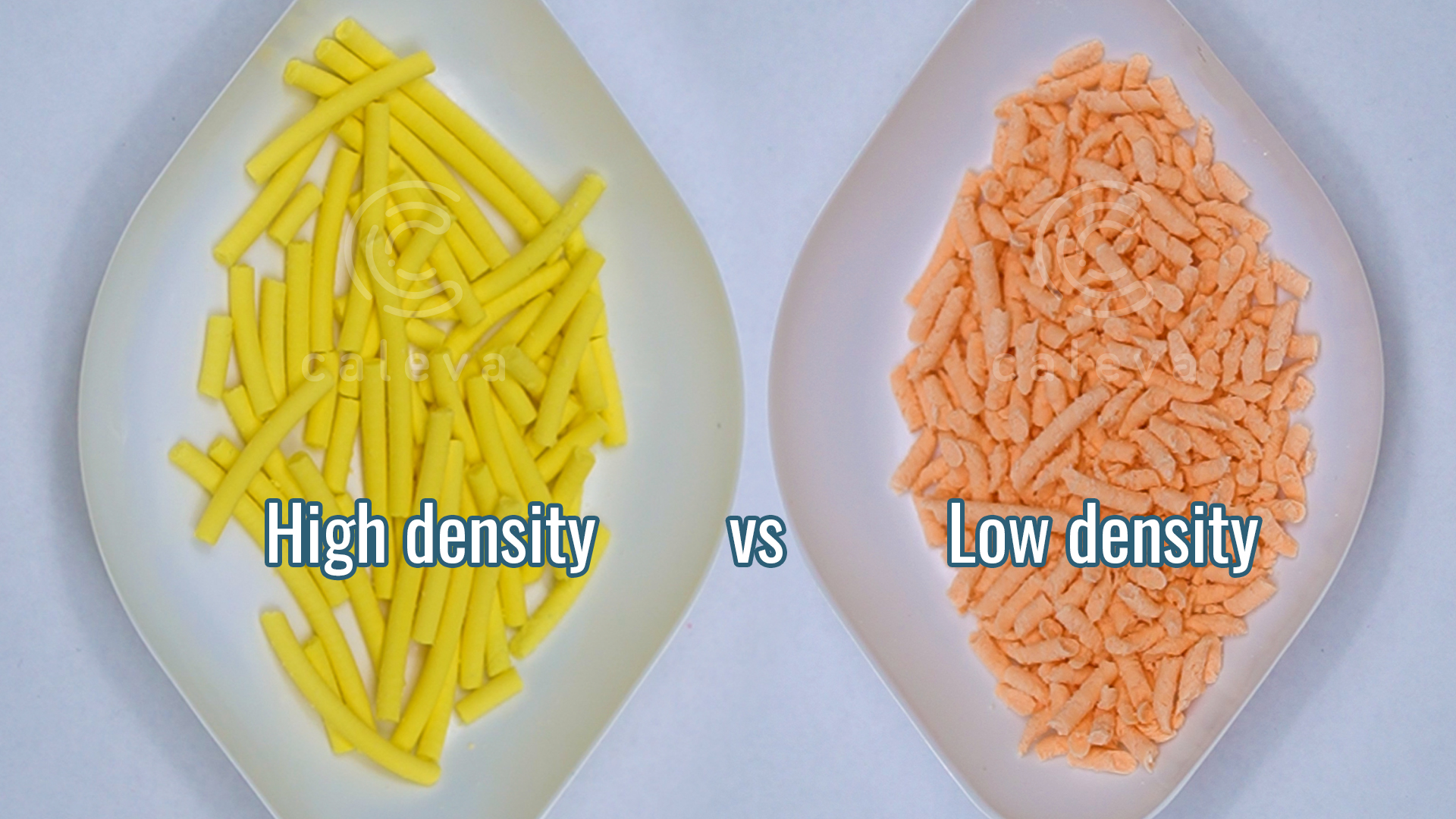

The Caleva CML extruder attachment is the smallest in the family of screw driven extruders that can offer the operator the ability to extrude the material at high, medium high, medium low, or low density. By management of the extrudate density physical properties of the extruded material can be influenced. The most important of these are likely to be:

Knowledge Base

Dr Steve Robinson

Recent Posts

Can I modify the density of extrudate produced during extrusion?

During the formulation development process, challenges related to final product performance have to be examined, exposed and overcome.

This is not always easy or straight-forward. However, if you have more options that you can investigate then there is likely to be an increased probability of a successful result. Different factors are considered as part of any formulation development and these...

Mixing trials with a Caleva Mixer Granulator and difficult materials

Two different products were tested to help a customer who was finding some difficulty in obtaining homogeneous mixes of small volumes. These materials were considered difficult to mix to a homogeneous state in the batch sizes required.

PRODUCT 1, TRIAL 1

A mix of sugar and salt in the ratio of 2:1

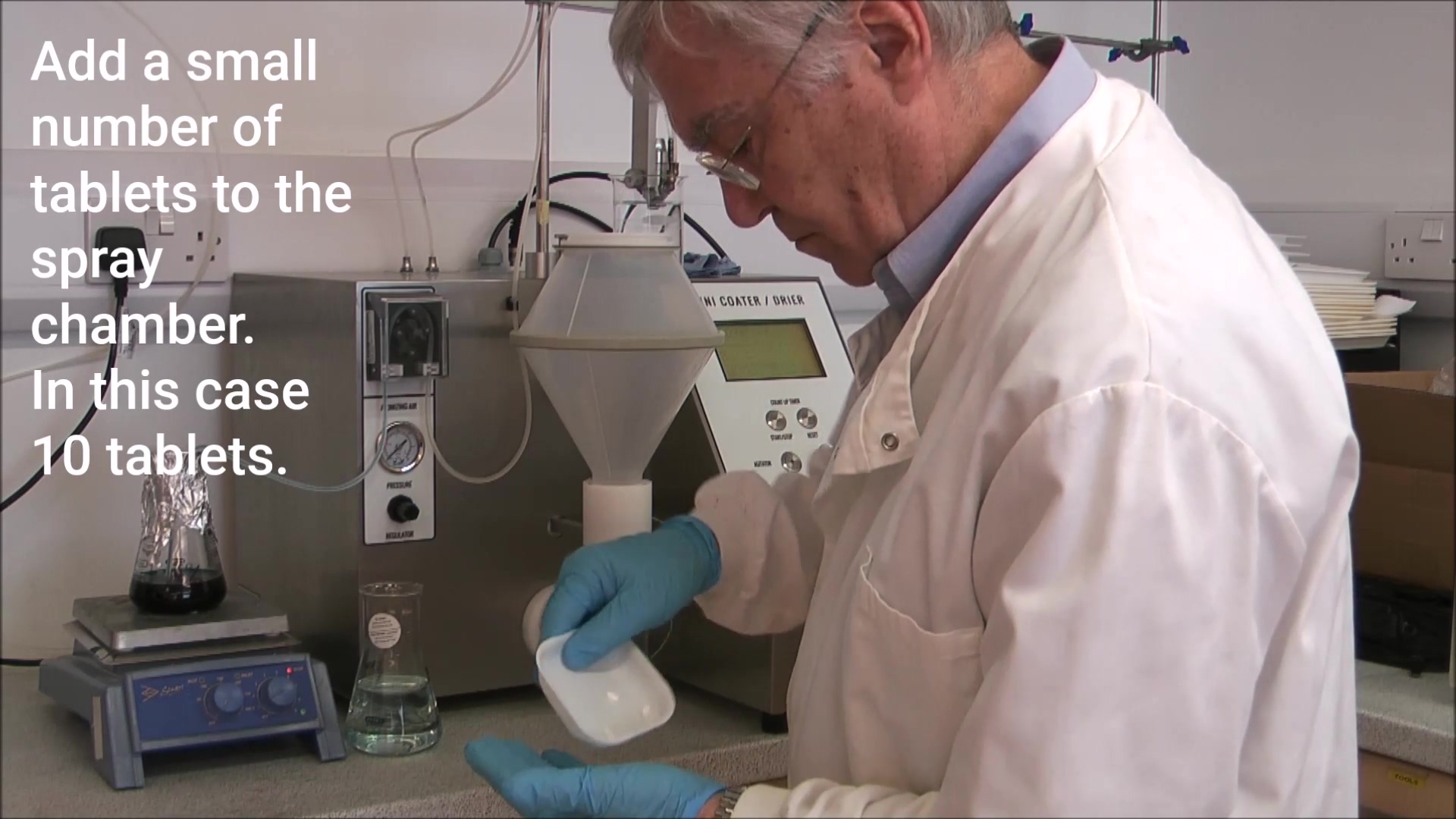

A batch of 100 grams of household sugar was weighed and added to the mixing bowl, together with a...How do I coat tablets or pellets with the Caleva Mini Coater Drier

The Mini Coater Drier (MCD) is an incredibly useful piece of equipment when it comes to coating and drying small batches of tablets or pellets. For a demonstration of the MCD in use, you can watch the video on this page, or for some quick pieces of information on the MCD, check the bullet points below.

- From a single tablet up to about 150 tablets

- From a few grams to about 60 grams of small...

Do excipients purchased from different vendors behave in the same way?

The Mixer Torque Rheometer can be used to assess the behaviour of excipients purchased from different suppliers.

Background

Excipients from different batches or vendors may be variable in quality and it is often necessary to perform pre-formulation assessment for each batch of excipient received. In some cases, excipients from different vendors require comparative assessment of their equivalent...

Can power use in granulation predict tablet dissolution & hardness?

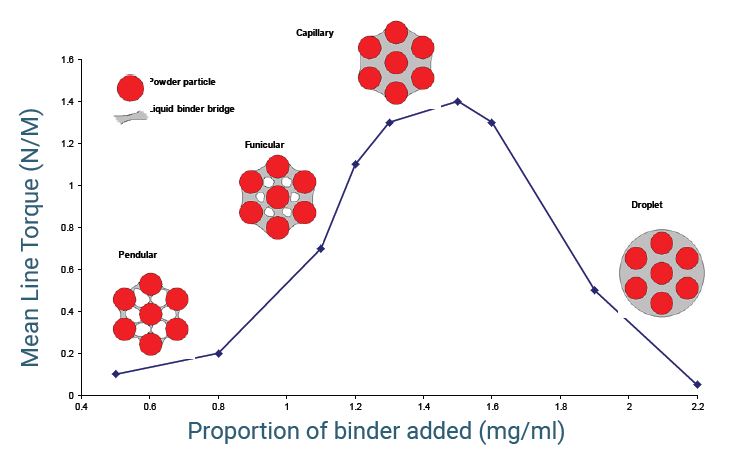

The recent research paper from Tomoto Otsuka et al (Chem. Pharm. Bull. 66, 554-561 2018) have shown that high shear granulation processes can influence final product properties such as tablet dissolution and hardness.The question raised by this paper was related to useful methods of evaluating the “kneading state” of a wet mass obtained during the granulation process. The most commonly used...

Inconsistent spheronization results with difficult active ingredient?

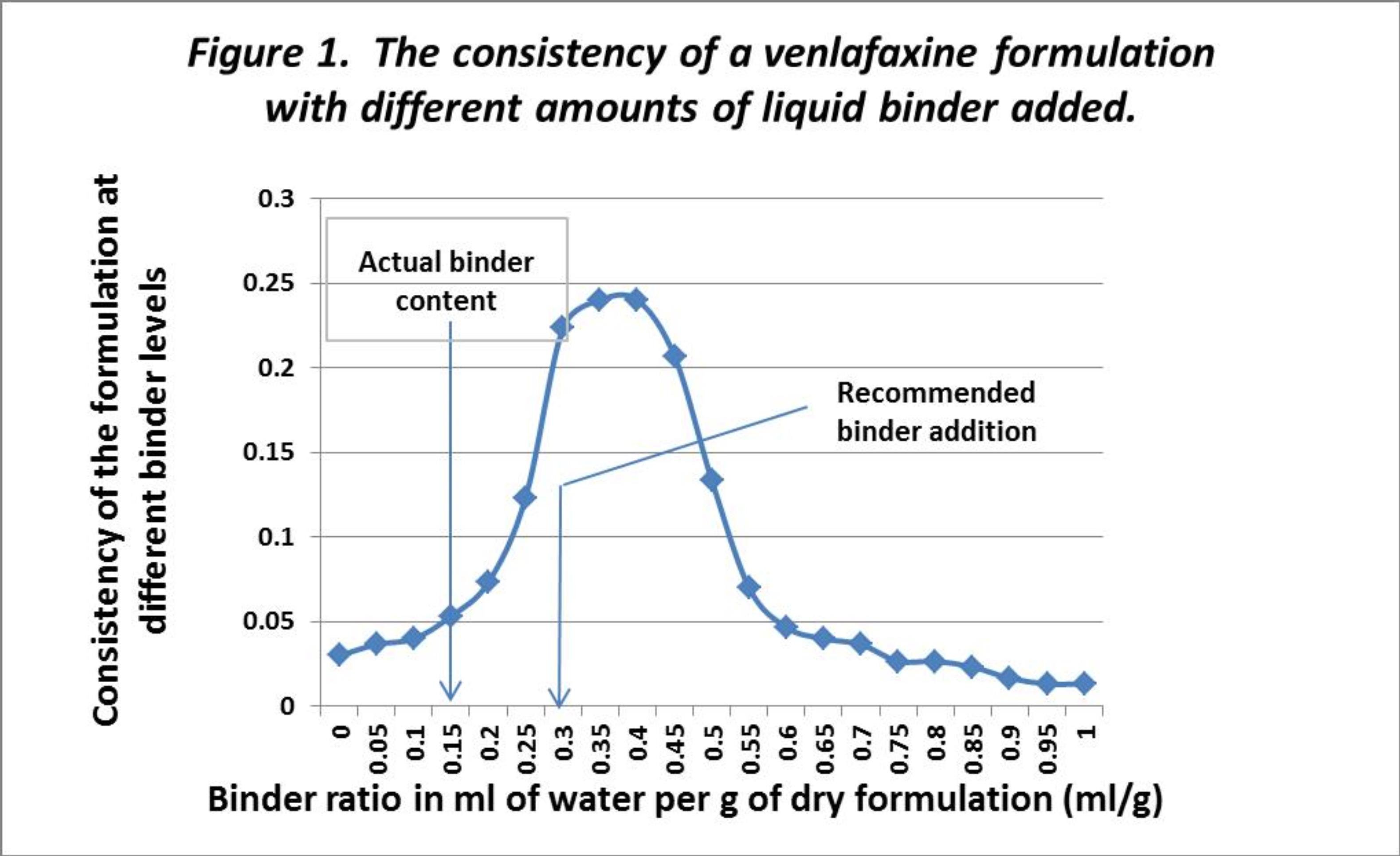

The following case study demonstrates how the Caleva Mixer Torque Rheometer. The MTR-3 was an invaluable aid in a specific case. A manufacturer of generic Venlafaxine pellets was experiencing inconsistent results from their manufacturing line. The resultant product was variable in both usable yield (weight of acceptable pellets as a % of weight of granulation made), and dissolution profile. The...

Caleva training seeks both successful and unsuccessful results - why?

Installation and training is generally specifically designed so that the operators and users can learn how to use the equipment and quickly learn through a series of procedures to produce acceptable results. However, our experience after several years of working with operators and researchers during installation and training, tells us that users learn more about the equipment and the technology...

How can I be sure that the trials and development work that I do will give me comparable results when I need to scale up to production sizes?

- The smallest extruder we offer is the Caleva Multi Lab (CML) with an extruder attachment designed to work with...

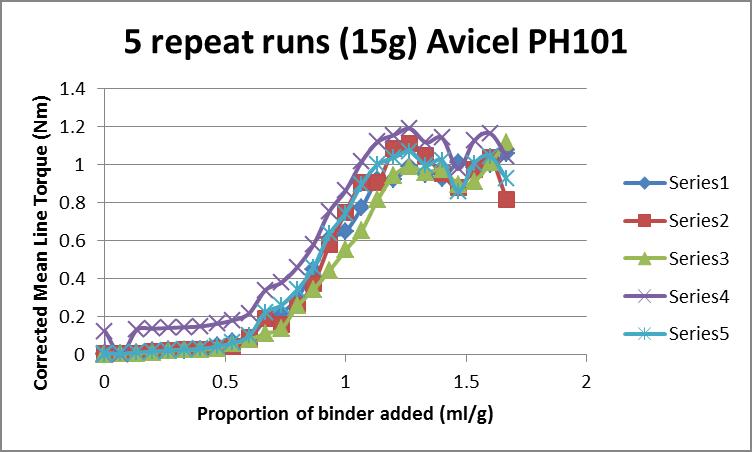

How reproducible can measurements be of something that is not homogeneous?

The MTR-3 uniquely offers a means of characterising the rheological properties of a wet granulation by providing a quantitative value of the consistency of the material tested. The more traditional hand squeeze test, previously widely used, to measure or compare granulations, is falling into disrepute and is no longer considered appropriate for modern day industrial production or research...

How the Mixer Torque Rheometer resolved a tablet friability issue

Caleva worked closely with a well known producer of food supplements made from natural materials, plant extracts and other natural food sources. Their tablet formulations work well and this nutraceutical company has a good reputation for their products. Generally they do not encounter problems with tablets breaking or disintegrating during manufacture, packing or storage.

Determination of moisture requirement to prepare spheroids by extrusion-spheronization

Spheroids are popularly used in the design of multi-particulate drug delivery systems. Extrusion and spheronization is commonly employed to manufacture spheroids in the pharmaceutical industry. It is a multiple-step manufacturing process which could be summarized into the flow chart as shown in Figure 1.

Save Time and Cost in Formulation Development

In the mid 1990’s, the field of pyrotechnics was limited mainly to applications in aircraft ordnance, fireworks and rock blasting. This has been developed to a highly advanced science and is an extensively used technology which finds application in spacecraft, aircraft and underwater vehicle systems. “Pyrotechnic “is defined as “explosive-actuated” and refers especially to devices in which...

End Point Determination Using the Caleva Mixer Torque Rheometer

A company wished to move a formulation currently undergoing product development from small scale laboratory (with batches of 50 grams) to the next stage for a larger scale batch trial of 100 kg (scale–up). The development had been started using a small Caleva Multi Lab bench top mixer (maximum batch capacity 50 gram of wet mass). This development had been successful and now additional samples...