We are frequently asked for information about the ability of the smallmixer/granulator/blender, a must have tool for any laboratory needing to complete these processes quickly with small sample sizes. Recent trials provide new information about the capability of the Caleva mixer/granulator/blender (MGB) and its ability to act as a stand alone mixer when mixing powder samples of different sizes...

Knowledge Base

Dr Steve Robinson

Recent Posts

Possible issues with extrusion of small samples - how to resolve them

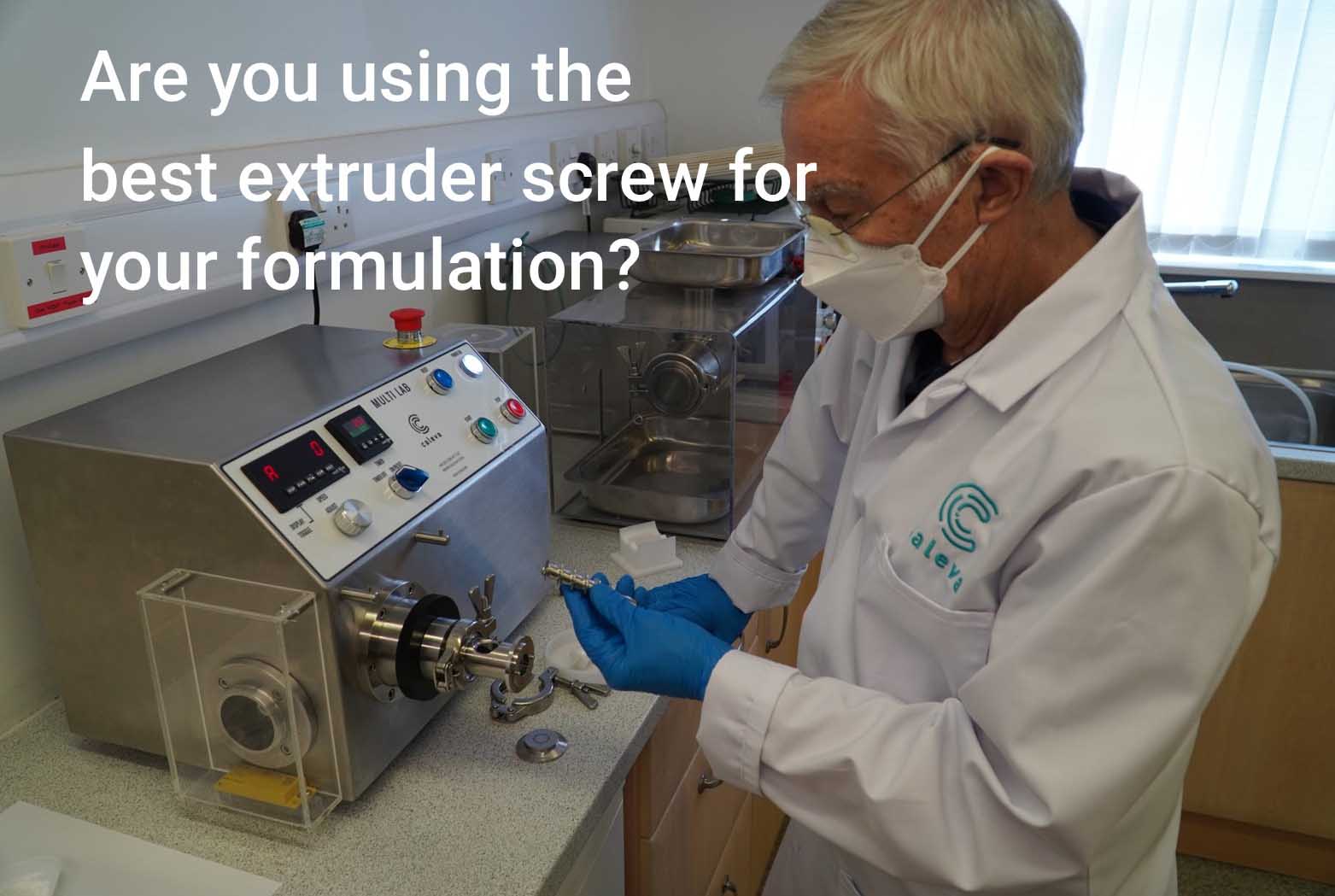

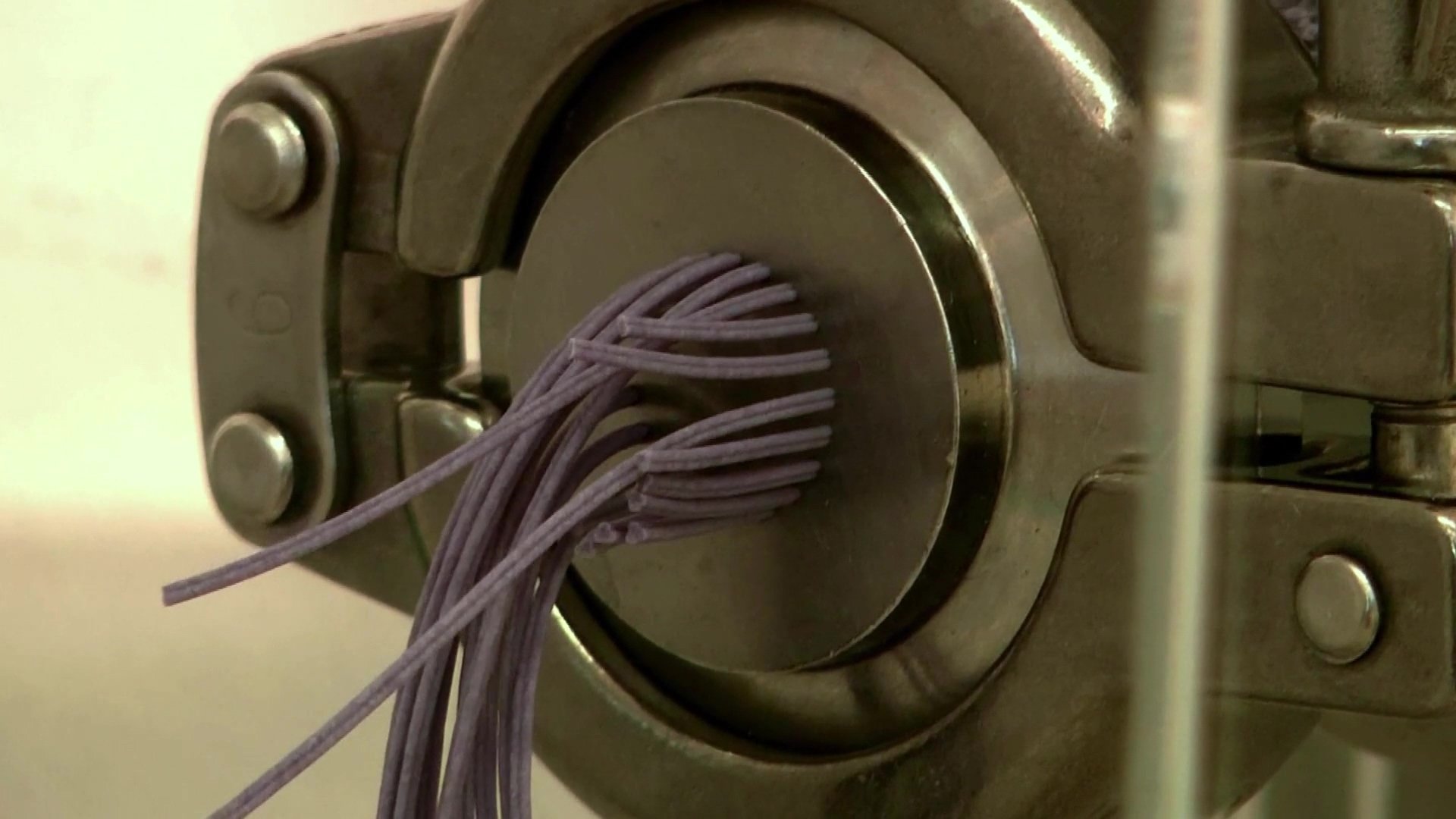

It is not possible to extrude and spheronize everything. Extrusion and spheronization can be used on a wide range of products and formulations. However, if you are having trouble extruding your formulations with the Caleva Multi Lab (CML) then please read this article.

Caleva offers extruder screws of different designs for use with the CML. If you are having issues with the CML then the first...

How much product should be used in the MTR and how accurate is it?

How much product do you use? The answer is that this is always product specific. This is demonstrated in this article. In these experiments the MTR is used in the multiple addition mode whereby increasing binder content is automatically added to different masses of product. The Caleva Mixer Torque Rheometer. The only way to quantify the rheology of a wet mass. The MTR has, for many years, been...

A better way to granulate with your viscous and sticky materials

Our new High Viscosity Mixing Blades, designed for making those sticky, viscous, difficult, granulations much simpler. Our design team have been working tirelessly to come up with a solution to a constantly asked question.

Extrusion of catalyst and petrochemical materials

An opportunity in laboratory extrusion with catalyst material. We have recently had some considerable success with one of our customers working with the extrusion of small quantities of catalytic material.

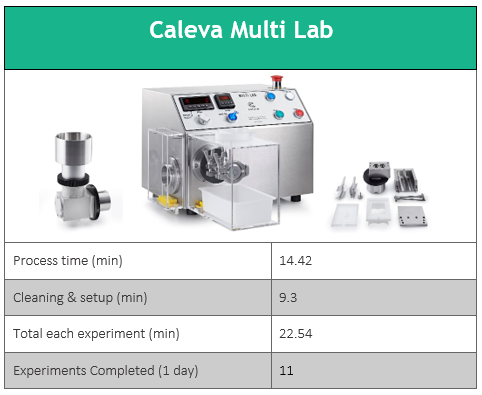

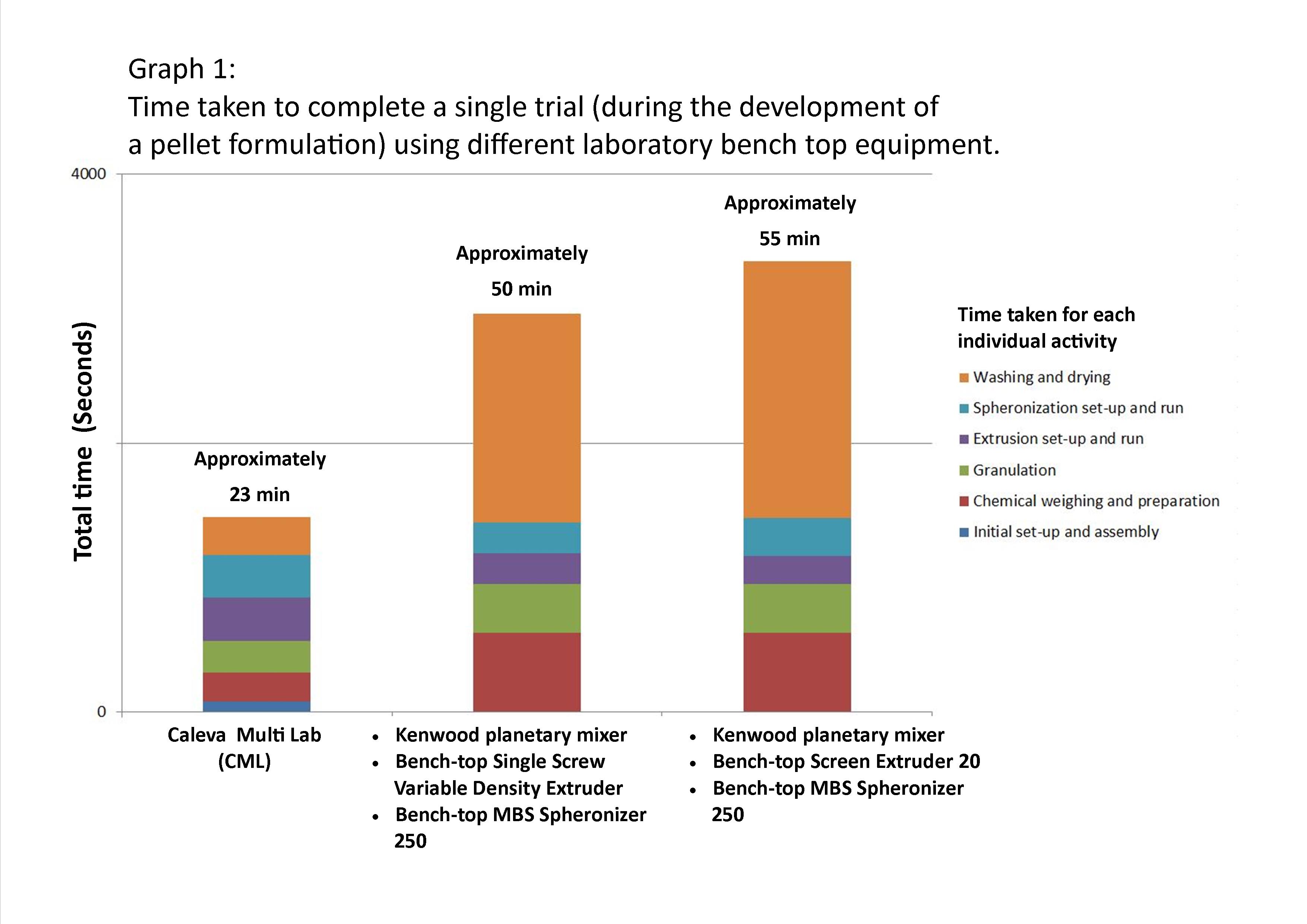

The Caleva Multi Lab is faster and easier to clean

The Caleva Multi Lab (CML) is faster and easier to clean than any comparable bench-top extrusion & spheronization equipment.

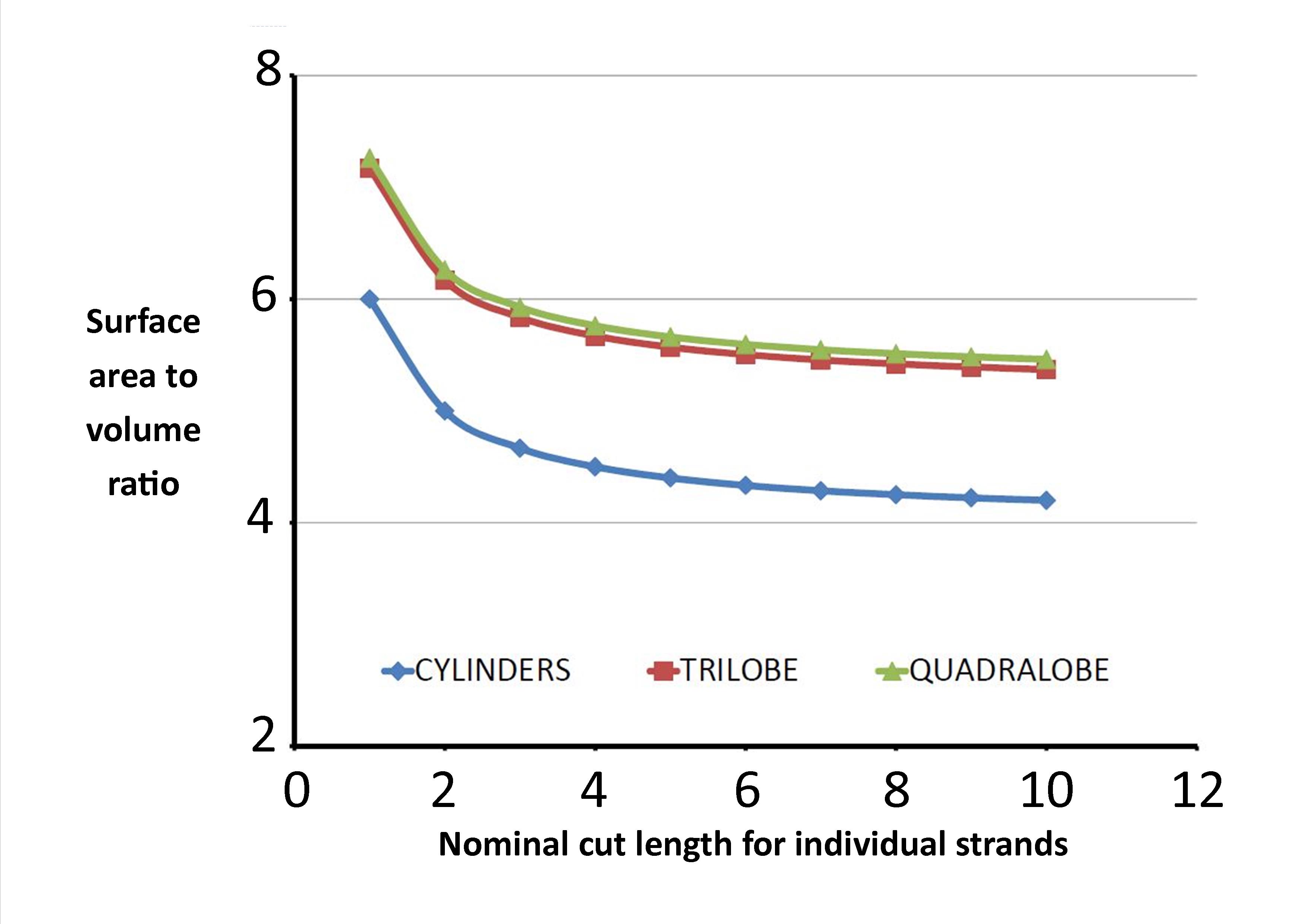

Guide to the optimum diameter to length ratio of extrudate fragments

Is there a guide to the optimum Length to Diameter ratio of the extrudate fragments?

In the calculations used to demonstrate the data it is assumed that the extrudate is an infinitely long strand. In this case the length of the extrudate has no influence on the data shown. In reality, extrudate is not infinitely long and as the individual strands of the extrudate produced become shorter, the...

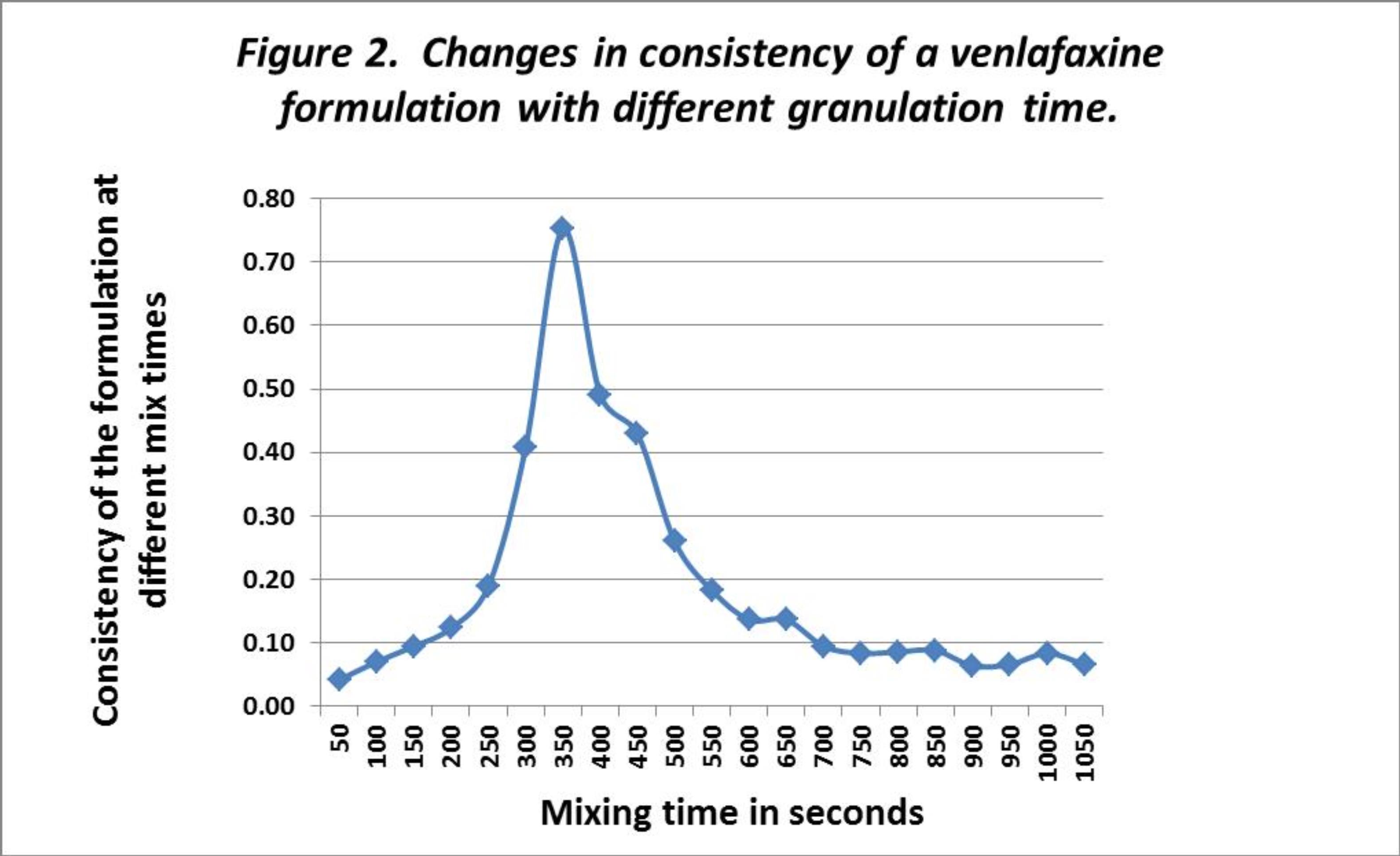

How long should I granulate my materials?

Variable Mix Time Test

It is well-known that a minimum amount of mixing is required to ensure consistent and repeatable product characteristics. What is often less considered is the possibility of over-mixing the product so that the characteristics of the resulting formulation undergo a change.

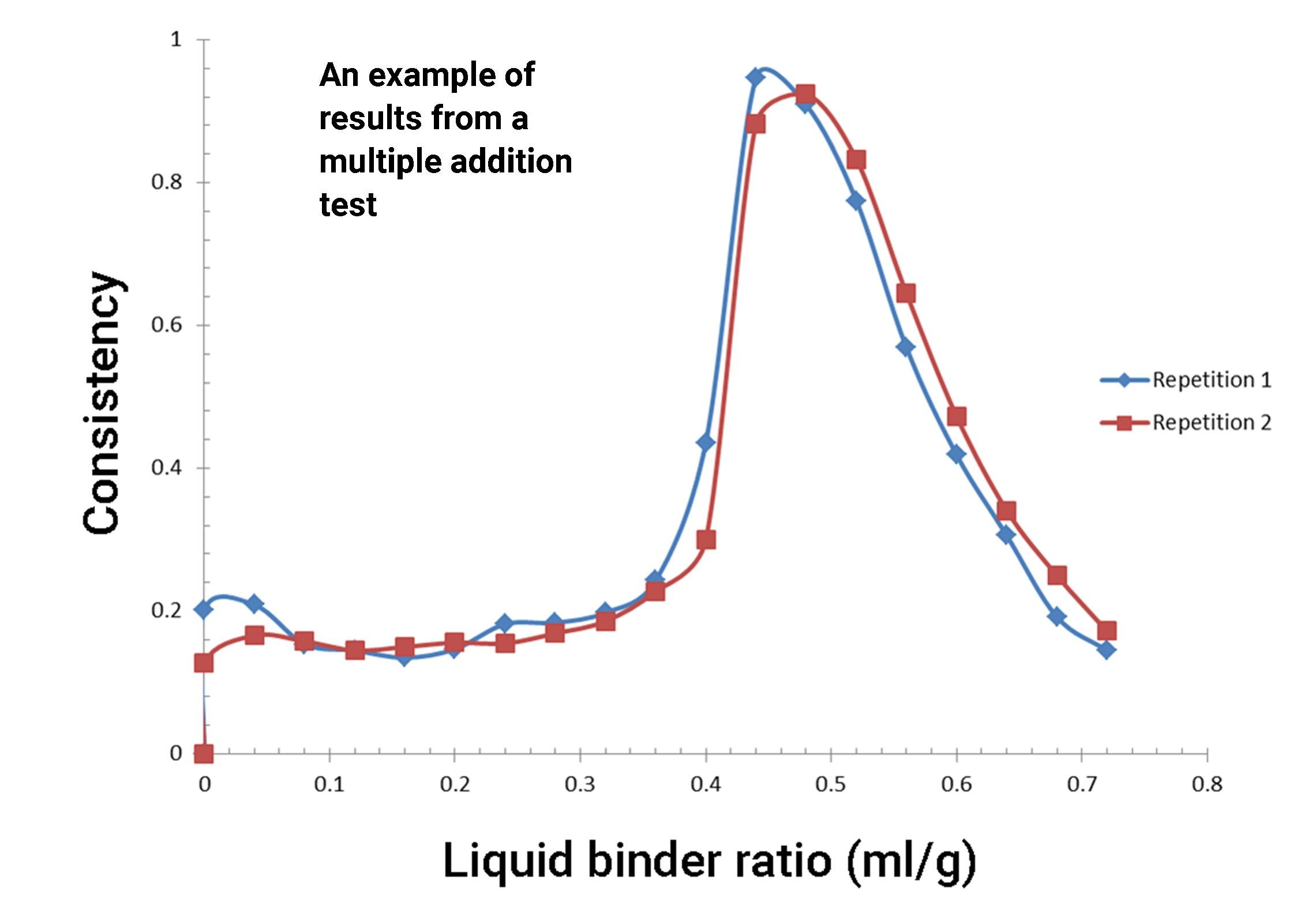

Formulation development - determine optimum powder to binder ratio

Multiple Addition Test

Binder liquid is added to a dry powder mix and the consistency is measured as the mixing and addition of binder progresses.

The consistency of the mix is measured at regular periods so that the relationship between the amount of liquid binder added to the mix and the consistency in the resulting formulation can be accurately shown.

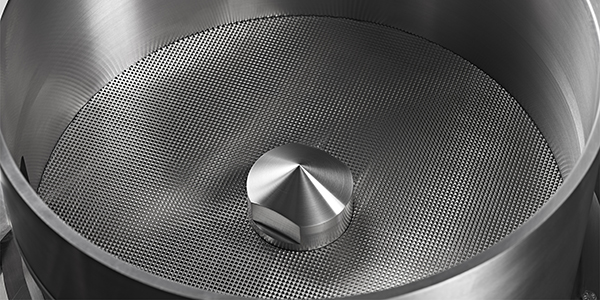

What is the smallest particle that I can coat in the Mini Coater Dryer

The Caleva MCD was originally designed for coating of very small batches of tablets. The original Mini Coater Drier was very efficient at this. However, as a response to several user comments and requests a new version was designed to allow users to also coat small samples of pellets over a range of industries. The original improved design specification that users were requesting was that batches...

What are the standard processes in the manufacture of pellets?

Wet Granulation - Granules are formed by the addition of a granulation liquid onto a bed of powder under the influence of an impeller. This is typically carried out using a high-shear granulator or a simpler planetary mixer.

Formulation development of catalyst materials zeolite and bentonite?

We always offer our potential users the opportunity to test their formulation with us in our lab. This is to ensure that installing our machines would be the right decision for their formulation development, and/or their production environment.

This short article has been written from notes that Dr Steve Robinson made during trials with catalysts sent to us by a customer and we achieved some...

Do I need to coat my pellets to prevent disintegration or dissolution?

We have been asked by a manufacturer (interested in looking at the development of Omeprazole formulations) if it was really necessary to coat these pellets with an enteric coating.

Do all extruders and spheronizers have the same level of performance?

Product yields (the percentage of the spheroids produced in a batch that are within the size range required) will never be 100%.

Developing a formulation with a tough waxy cosmetic material

We recently had a visitor from Asia who was trying to solve a problem with their cosmetic formulation. The investigator wished to have approximately 1 mm diameter pellets. The formulation presented was a tough, waxy material in irregular broken blocks that were up to about 10 mm in diameter and was unable to be spheronized into the required size or shape.

Can I spheronize a granulation and skip the extrusion process?

In some circumstances it is possible to omit the extrusion stage, but the results may not be what you need.

It is dependent on what you need to achieve with your result and what you want to do in the next phase of the project. Whether or not you decide to include the extrusion stage will depend on what you want to achieve with your project.

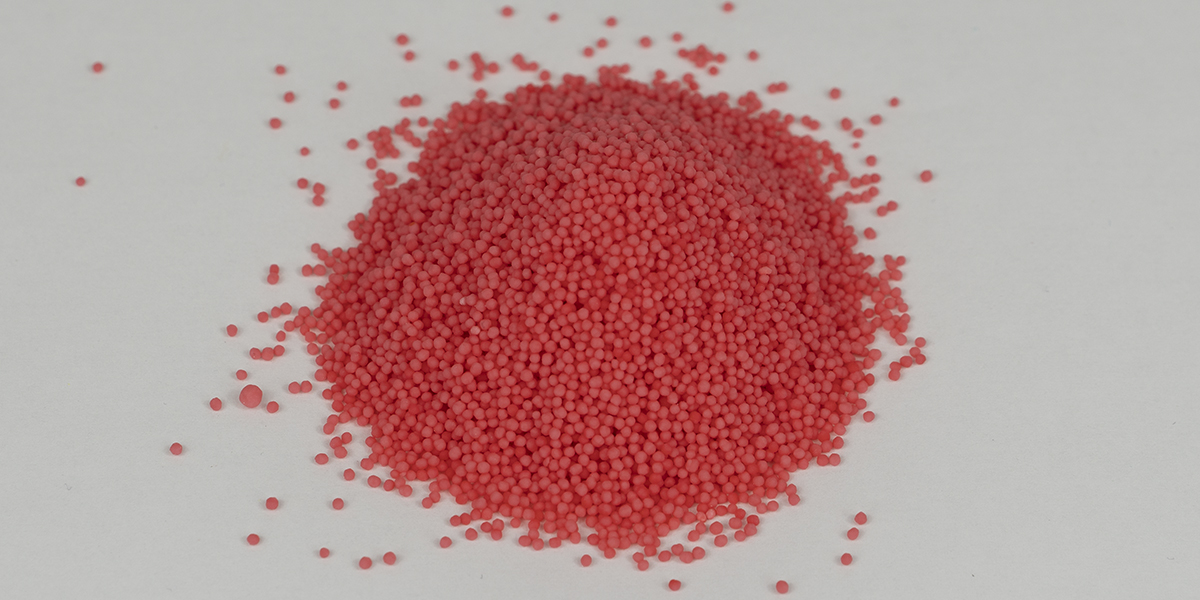

Examples of the terminology used in spheronization and marumerization

Spheronization, marumerization, pelletization and micropelletization all mean the same thing. The manufacture of products in small spheres (spheroids) for use in pharmaceutical (pharma) and catalyst industries. Within each batch the spheroids are of regular shape and size and are quite dense. The products produced by these processes can be called spheroids, spheres, micro-spheres, pellets,...

Mix sticky, viscous and difficult granulations

High Viscosity Blade & Bowl set from the Caleva Multi Lab. Mix and blend small quantities of difficult materials using the special high viscosity bowl and blade attachment set built for the Caleva Multi Lab.Our high viscosity mixing bowl and blade set is designed for mixing and blending of small quantities (10 to 50 g) of those more difficult and more viscous mixtures when the high shear standard...

Do I need a water jacket for cooling on a screw extruder?

The extruder attachment on the Caleva CML does not have a water jacket. Does it need one?

All extruders generate heat and screw extruders generate more than most other extruder types. For this reason, water jackets are generally an integral part of single or twin-screw extruders.

- Given the small batch sizes (10 to 100 g) that are optimum for the CML extruder, a well formulated extrudate will...