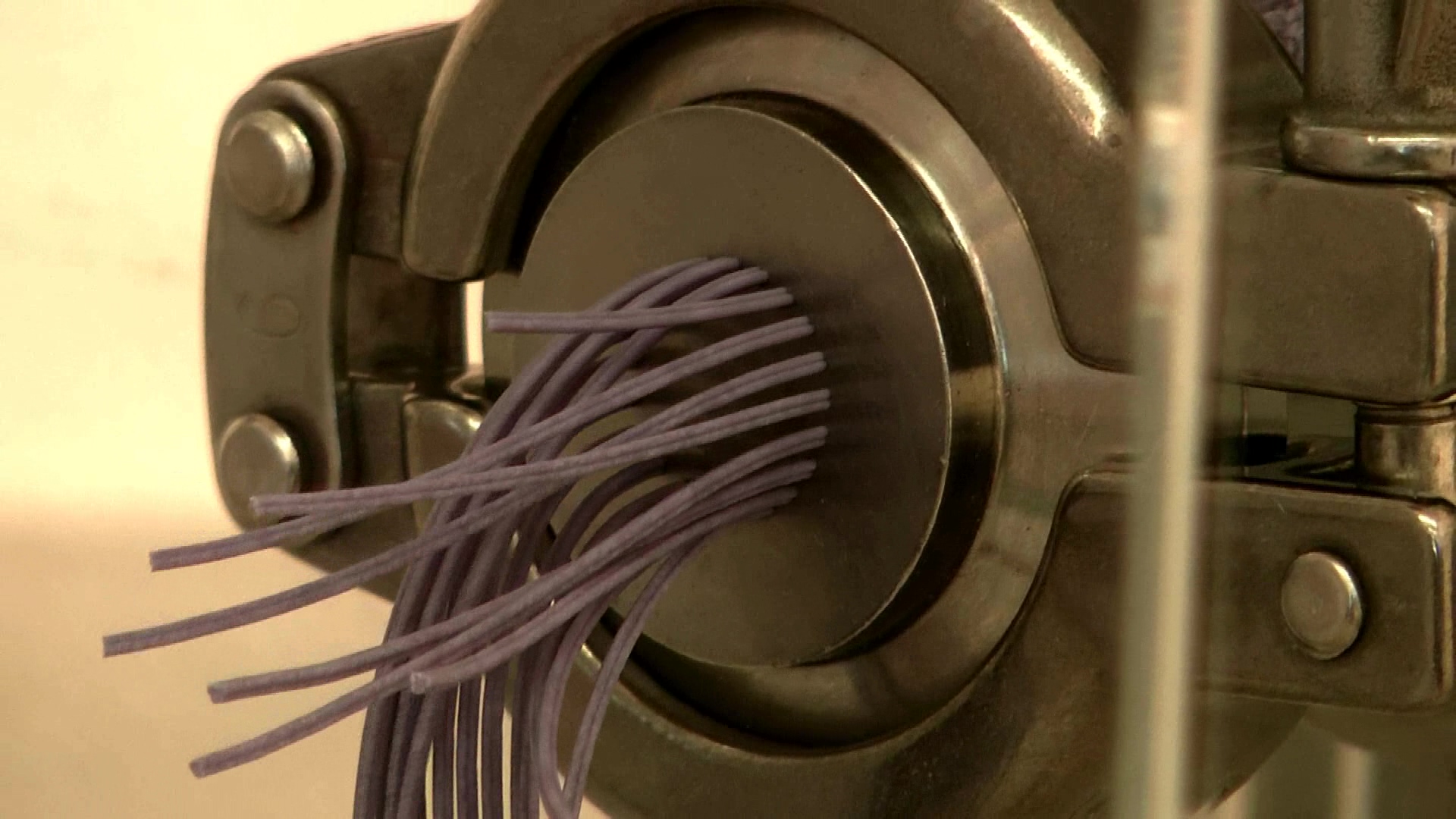

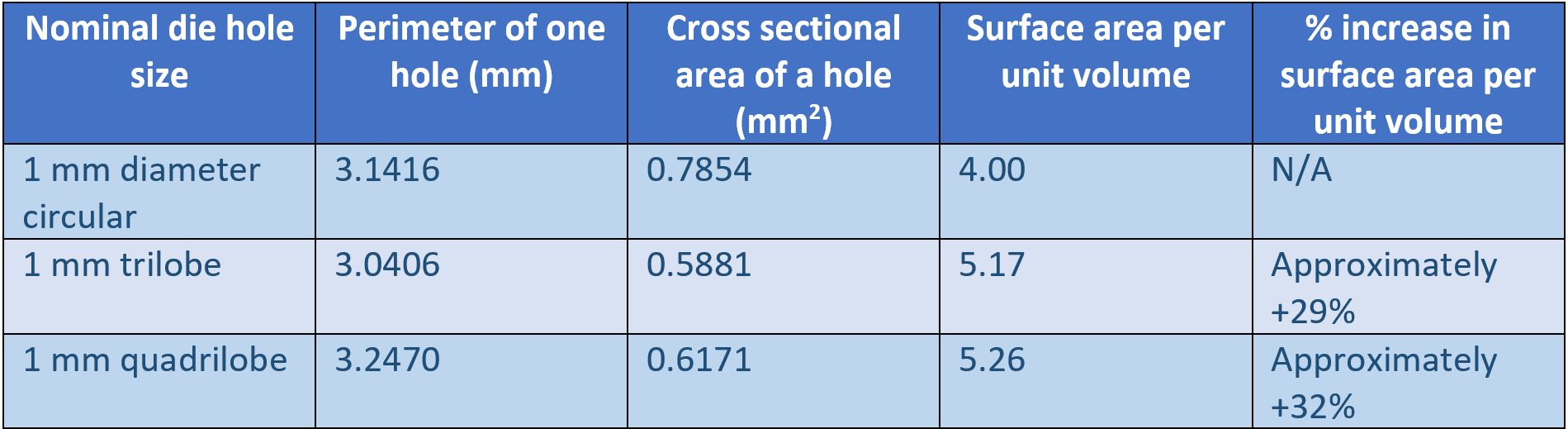

Can trilobe and quadrilobe extruder dies provide benefits when working with catalysts or products for gas adsorption?

Knowledge Base

Dawn Philips

Recent Posts

Increase the Surface Area to Volume Ratio in the Extruded Material

Can the equipment design help to increase the surface area to volume ratio (SA/V) in the extruded material (extrudate)?

How do I Decide Which Laboratory Extruder and Spheronizer I Need?

We are often asked for advice by researchers and teachers who want to acquire laboratory equipment for wet granulation formulation development using the extrusion and spheronization process. However, we typically find that all our equipment users have different requirements. Caleva offer a range of different solutions for extrusion and spheronization in your lab or teaching space. Each solution...

Is there a correctly sized extruder die to get the size of pellets you need?

There is no simple answer to this question as it depends on the characteristics of your formulation and the size of the pellets you require.

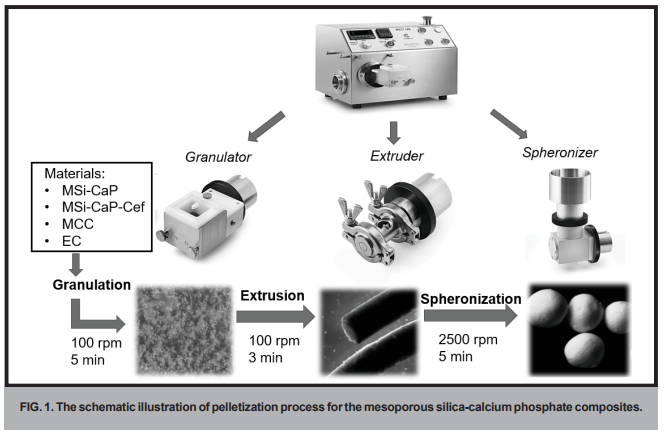

Caleva Multi Lab & Bone Regeneration study Medical University Gdańsk

Drug-loaded mesoporous silica/calcium phosphate composites for bone regeneration

Adrian Szewczyk at Department of Physical Chemistry, Faculty of Pharmacy, Medical University of Gdańsk has kindly allowed us to introduce this paper that introduces a study of Drug-loaded mesoporous silica/calcium phosphate composites for bone regeneration.

Yield Problems in Production and Quality Control

One of the strengths of the Caleva Mixer Torque Rheometer (MTR-3) is that it can be used to verify the properties of wet powder mass samples taken during production in large scale mixer/granulator systems.

Do you have heat generation issues with your extrusion process?

During production scale extrusion heat is generated as a result of the process. The amount of heat generated will vary depending on:

- The formulation of the product

- The rate of extrusion

- The physical specifications of the extruder

- The type of extruder being used, for example, screw, gear, or basket.

The importance of mixing time for formulation development

It is well established and understood that one of the most important factors in the development of a formulation for both tableting and making pellets by extrusion and spheronization is the amount of liquid binder added to the formulation. What is less widely acknowledged is the importance of mixing and the mixing regime used.