Shaped Catalyst Body Preparation. Zeolite HZSM-5 (ACS Materials, M38) was mixed as a dry powder with alumina (Sasol, Catapal D (Boehmite)) and the required amount of Milli-Q water to ensure an optimum solid-to-liquid ratio for extrusion (measured using a Mixer Torque Rheometer, Caleva). The paste, containing a ratio of 70:30 wt % zeolite:binder, was extruded using a Mini-Screw Extruder (Caleva),...

Knowledge Base

Recent Posts

Mix, Extrude & Spheronize in a single base - watch a video

Call Caleva's friendly team to talk about this unique solution for your applications, whatever your challenges are.

The Caleva Multi-Lab (CML) is often considered to be the flagship of Caleva lab equipment.

Being able to perform 3 different processes rapidly in one machine with a footprint just slightly larger than an A3 piece of paper, makes the CML a welcome addition to any lab space that...

The very small footprint Caleva Multi Lab

The small size of the CML is just one of the many advantages that this piece of equipment can offer. Having the ability to complete 3 processes in one machine, whilst also taking up a minimal amount of bench top space, makes the CML a great addition to any lab space that works with the processes of mixing/granulation, extrusion and spheronization.

The Caleva Family of Laboratory Equipment

Whilst you may have heard of Caleva and any one of its flagship pieces of equipment, we'd like to introduce you to the family of Caleva laboratory equipment that you may find helpful for your application in your industry sector. Choose one process or choose all of them. Select further functions as you need them. This adaptable and future proof suite of equipment will allow you to obtain proof of...

Mixer Torque Rheometer used with Food Powders

Research Article University of Padova where their Caleva Rheometer was used

Abstract

Vegetable soups are complex mixtures containing vegetables in different percentages, thickeners, salt, fat, and emulsifying/wetting agents. When prepared as dehydrated powders in convenience foods, they need to be rehydrated before consumption and this can lead to formation of undesired lumps when...

Mini Coater Dryer (air suspension coater) used in formulation development

Tablets were coated with a color overcoat (Aquarius Cool Vanilla BI-1800,Ashland/Aqualon; hydroxypropylmethylcellulose, titanium dioxide, triacetin, polysorbate)using a Caleva air-suspension coater to 2-4% by weight …

Caleva Mixer working in catalyst application for Ethylene and Propylene

Components were mixed with a specialist Caleva mixer to form a homogeneous paste

Agglomeration properties of gluten-free flours under water addition and shearing conditions

The different states of agglomeration were identified by the evolution of rheological properties under water addition and shearing conditions using a Caleva®mixer torque rheometer.

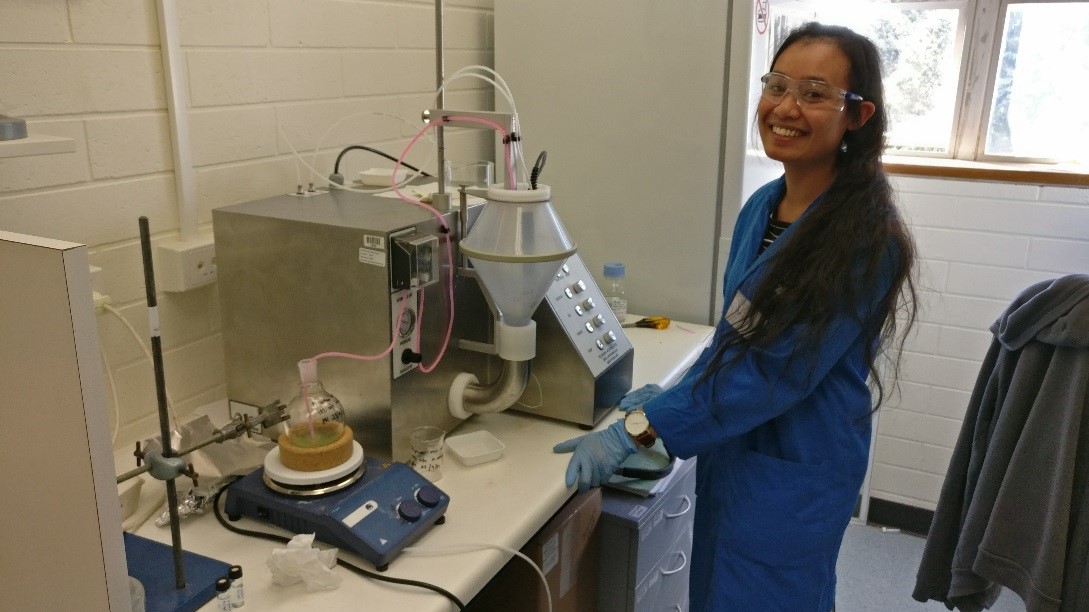

Caleva Mini Coater Drier Helps to Reintroduce Endangered Native Australian Animals

Many experts recognise Caleva as a leading manufacturer in extrusion and spheronization equipment for the development of pharmaceutical formulations, catalysts and ceramics. However, the broard scope and flexibility of Caleva equipment provides diverse capabilities that is leading to emerging applications in implant manufacture and conservation science. To explain more, we caught up with Dr Anton...

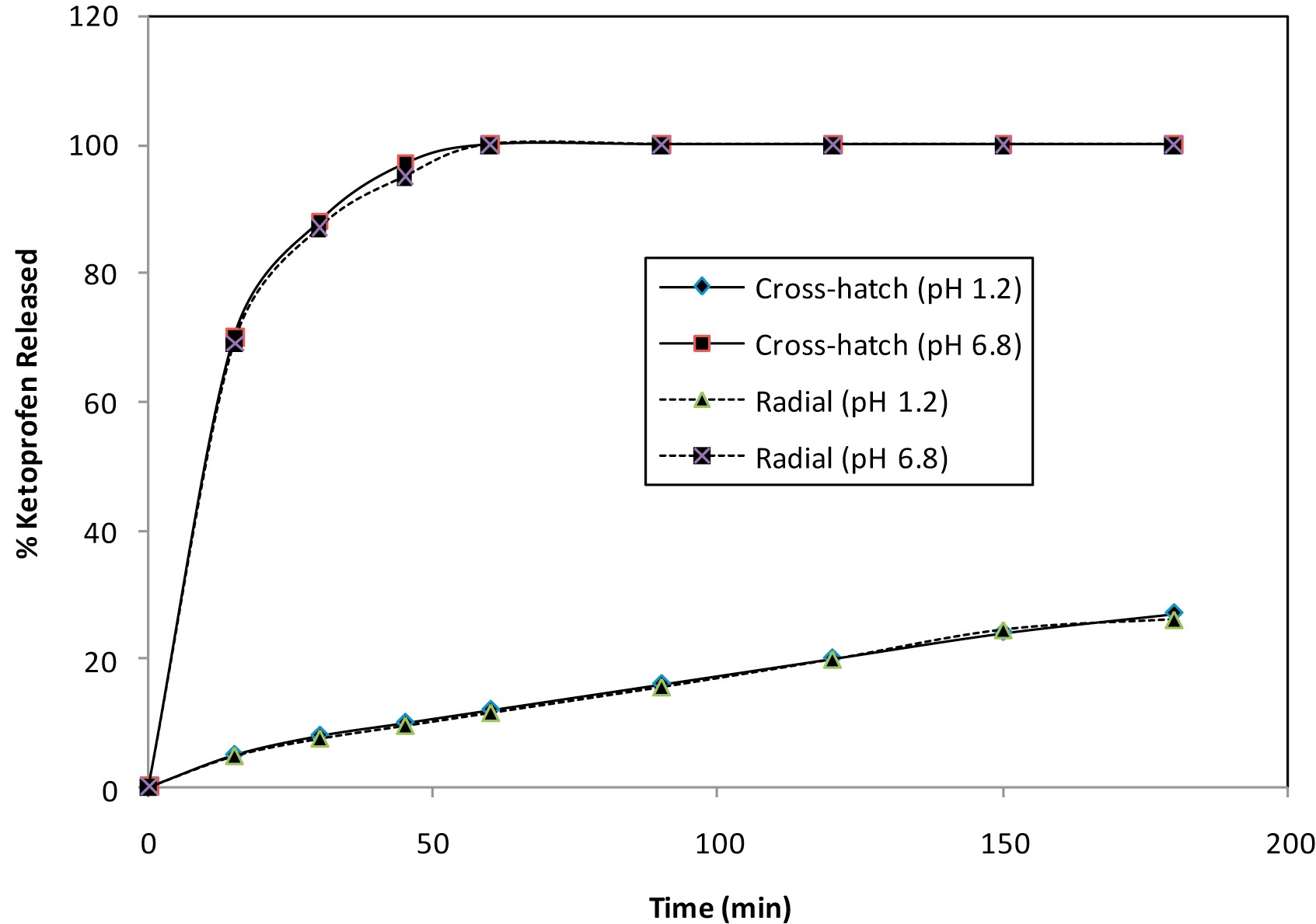

Effect of spheronizer plate design on the spheronization of ketoprofen

Abstract: Spheronization is a rapid process for production of microspheres. The process involves the dry mixing of drug with microcrystalline cellulose (MCC), which on subsequent wetting with water forms a plastic mass suitable for extrusion and spheronization. As in any pharmaceutical operation, large number of factors may affect the production of pellets, which can be related to formulation or...

Extrusion–spheronization a promising pelletization technique: In-depth review

Abstract

This review article deals with various aspects of the extrusion–spheronization technique. The first part includes different steps in the production process of pellets such as granulation, extrusion, spheronization, and drying. In the second part, the parameters which can influence the quality of pellets including formulation (moisture content, granulating liquid,excipients, and...

Catalyst Pellets cracked! The strange apple sauce method

Over the past couple of years I have worked with a huge number of chemical engineering teams, trying to crack the optimum base for a catalyst pellet. After hours of trials and research, I am pleased to say, we’ve done it!

Spheronization Barrier Technique from Caleva

OK, so this was a tip I discovered a while back, but now it’s becoming more and more beneficial for me in practice when working with sticky, viscous materials. Perhaps this will help you too?